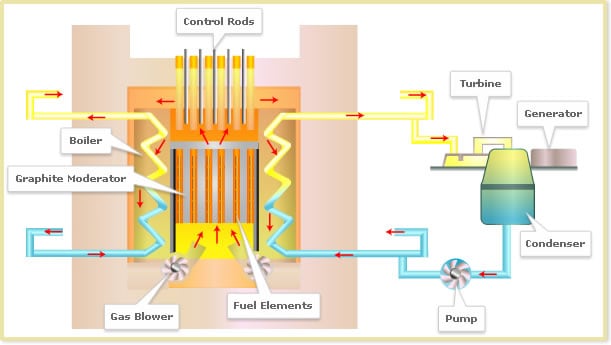

AGRs were developed from the Magnox type reactor.These are the second generation of British gas-cooled reactors. AGRs are operating at a higher gas temperature for improved thermal efficiency, thus requires stainless steel fuel cladding to withstand the higher temperature. Because the stainless steel fuel cladding has a higher neutron capture cross section than Magnox fuel (magnesium non-oxidising alloy), low enriched uranium fuel is needed.

The fuel is uranium oxide pellets, enriched to 2.5-3.5%, in stainless steel tubes. The carbon dioxide circulates through the core, reaching 650°C (for improved thermal efficiency) and then past steam generator tubes outside it, but still inside the concrete and steel pressure vessel (hence ‘integral’ design). Control rods penetrate the moderator and a secondary shutdown system involves injecting nitrogen to the coolant.

Source: www.hknuclear.com