Pump Efficiency

Pump efficiency is the ratio of the water horsepower delivered by the pump and the brake horsepower delivered to the pump shaft. When selecting a pump, a key concern is optimizing pumping efficiency. The energy usage in a pumping installation is determined by the flow required, the height lifted, and the length and friction characteristics of the pipeline. The power required to drive a pump is defined simply using SI units by:

where:

- P is the input power required (W)

- BHP is the brake horsepower

- ρ is the fluid density (kg/m3 )

- g is the standard acceleration of gravity (9.81 m/s2 )

- H is the net pump head added to the flow (m)

- Q is the flow rate (m3 /s)

- η is the efficiency of the pump

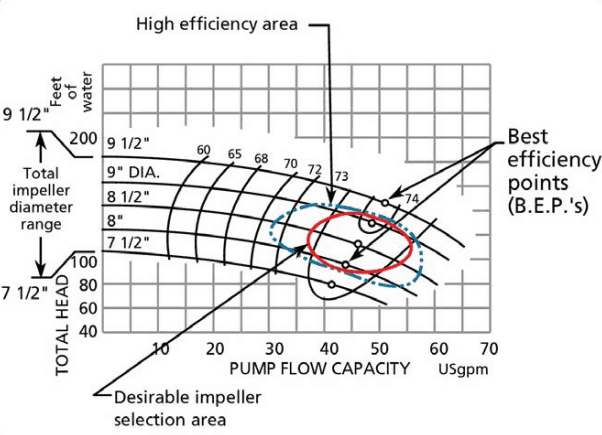

Best Efficiency Point

The best efficiency point (BEP) is the point of the highest efficiency of the pump. It is an internal characteristic of each centrifugal pump. It must be noted and any pump does not completely convert kinetic energy to pressure energy. Some of the energy is always internal or external lost.

The best efficiency point (BEP) is the point of the highest efficiency of the pump. It is an internal characteristic of each centrifugal pump. It must be noted and any pump does not completely convert kinetic energy to pressure energy. Some of the energy is always internal or external lost.

The internal losses are caused by fluid friction in the impeller due to rapid change in flow direction and change in velocities throughout the pump. The external losses are caused by mechanical losses in seals and bearings. All points to the right or left of the BEP have a lower efficiency. Pumps should be sized as close as possible to their best efficiency point or flow rate. This not only makes the pump more efficient but also improves its reliability of the pump. Note that total efficiency is never realized because of mechanical and hydraulic losses incurred in the pump.

Impeller design is the most significant factor for determining the BEP of a pump because it determines how efficiently power (brake horsepower or BHP) is transmitted to the liquid being pumped. A properly designed impeller optimizes flow while minimizing turbulence and maximizing efficiency.