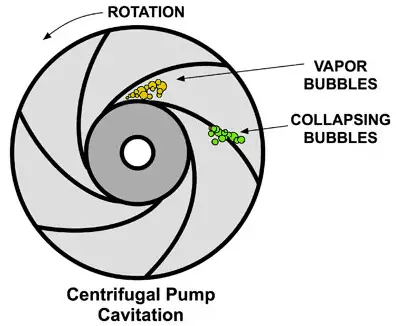

Suction cavitation, or classic cavitation, occurs when a pump is under low pressure or high vacuum conditions. When the liquid being pumped enters the eye of a centrifugal pump, the pressure is significantly reduced. In some cases, the pressure drop is great enough to cause the liquid to flash to steam when the local pressure falls below the saturation pressure for the fluid that is being pumped. Bubbles or cavities will form at the eye of the impeller, and subsequently, the formed vapor bubbles move into regions of higher pressure as they travel towards the pump discharge. In the higher pressure region, the vapor bubbles collapse suddenly on the outer portions of the impeller. This can cause significant damage to all moving parts of a centrifugal pump.

Suction cavitation, or classic cavitation, occurs when a pump is under low pressure or high vacuum conditions. When the liquid being pumped enters the eye of a centrifugal pump, the pressure is significantly reduced. In some cases, the pressure drop is great enough to cause the liquid to flash to steam when the local pressure falls below the saturation pressure for the fluid that is being pumped. Bubbles or cavities will form at the eye of the impeller, and subsequently, the formed vapor bubbles move into regions of higher pressure as they travel towards the pump discharge. In the higher pressure region, the vapor bubbles collapse suddenly on the outer portions of the impeller. This can cause significant damage to all moving parts of a centrifugal pump.

Typical causes of suction cavitation:

- The pump is running too far right on the pump curve

- Poor suction conditions (NPSH requirements)

- Blockage in the pipe on the suction side

- Inappropriate piping design

- Clogged filters or strainers

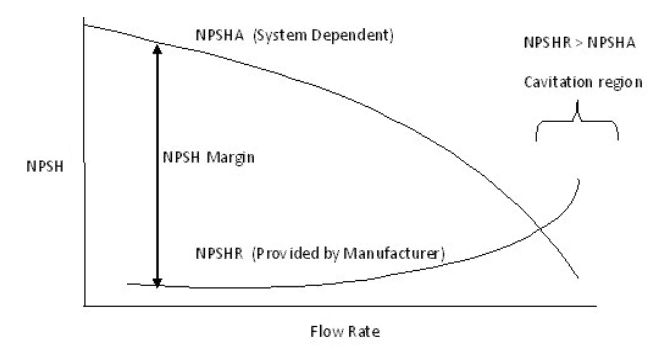

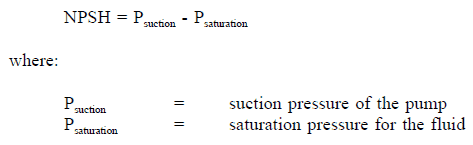

To prevent this type of cavitation, the Net Positive Suction Head Available (NPSHa) in the system must be higher than the required NPSH of the pump. This problem is typical for suction cavitation, and therefore this type of cavitation is also called inadequate NPSHa cavitation.

Besides the change of the pump, problems with suction cavitation can also be solved by:

- Lowering the temperature

- Reduction of motor RPM if possible

- Increase in the diameter of the eye of the impeller

- Use of an impeller inducer.

- Use of two parallel pumps with lower capacity.

- Use of a booster pump to feed the principal pump.

Special case of cavitation occurs at the suction side as a result of inappropriate piping in suction line. Use of restrictions, sharp elbows and other hydraulic equipment can turbulize the flow this can contribute to cavitation formation.