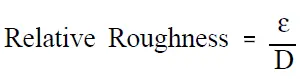

The quantity used to measure the roughness of the pipe’s inner surface is called the relative roughness, and it is equal to the average height of surface irregularities (ε) divided by the pipe diameter (D).

where both the average height surface irregularities and the pipe diameter are in millimeters.

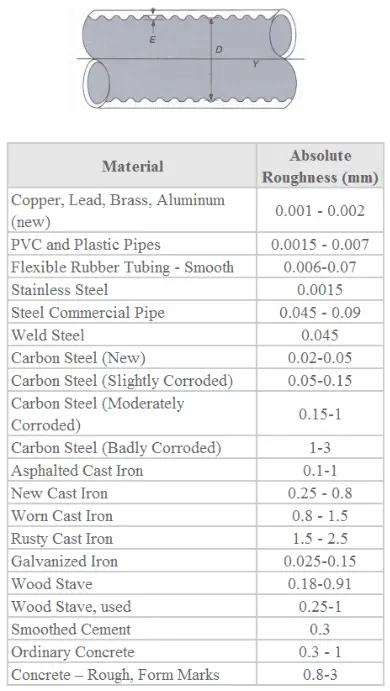

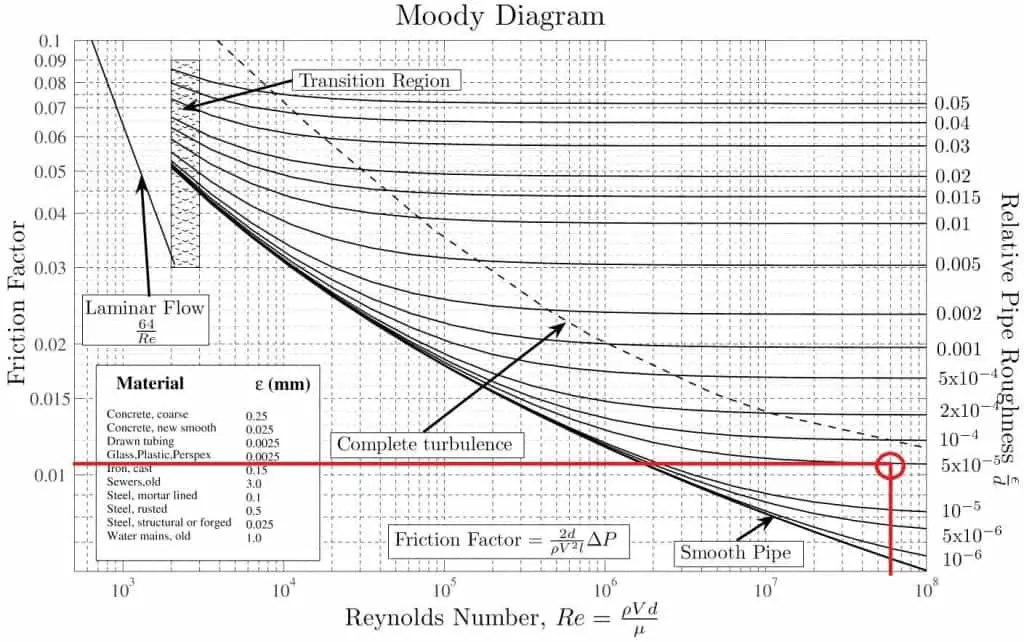

If we know the relative roughness of the pipe’s inner surface, then we can obtain the value of the friction factor from the Moody Chart.

The Moody chart (also known as the Moody diagram) is a graph in the non-dimensional form that relates the Darcy friction factor, Reynolds number, and the relative roughness for fully developed flow in a circular pipe.

Summary:

- Head loss of the hydraulic system is divided into two main categories:

- Major Head Loss – due to friction in straight pipes

- Minor Head Loss – due to components as valves, bends…

- Darcy’s equation can be used to calculate major losses.

- The friction factor for fluid flow can be determined using a Moody chart.

- The friction factor for laminar flow is independent of the roughness of the pipe’s inner surface. f = 64/Re

- The friction factor for turbulent flow depends strongly on the relative roughness. The Colebrook equation determines it. It must be noted that the friction factor is independent of the Reynolds number at very large Reynolds numbers.

Why is head loss very important?

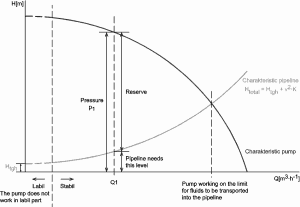

As can be seen from the picture, the head loss is formed key characteristic of any hydraulic system. In systems in which some certain flowrate must be maintained (e.g.,, to provide sufficient cooling or heat transfer from a reactor core), the equilibrium of the head loss and the head added by a pump determine the flow rate through the system.

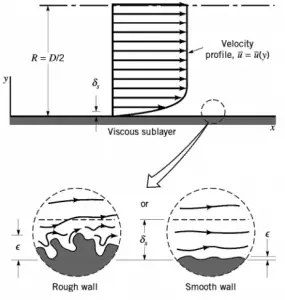

It must be noted, at very large Reynolds numbers, the friction factor is independent of the Reynolds number. This is because the thickness of the laminar sublayer (viscous sublayer) decreases with increasing Reynolds number. For very large Reynolds numbers, the thickness of the laminar sublayer is comparable to the surface roughness, and it directly influences the flow. The laminar sublayer becomes so thin that the surface roughness protrudes into the flow. The frictional losses, in this case, are produced in the main flow primarily by the protruding roughness elements, and the contribution of the laminar sublayer is negligible.

It must be noted, at very large Reynolds numbers, the friction factor is independent of the Reynolds number. This is because the thickness of the laminar sublayer (viscous sublayer) decreases with increasing Reynolds number. For very large Reynolds numbers, the thickness of the laminar sublayer is comparable to the surface roughness, and it directly influences the flow. The laminar sublayer becomes so thin that the surface roughness protrudes into the flow. The frictional losses, in this case, are produced in the main flow primarily by the protruding roughness elements, and the contribution of the laminar sublayer is negligible.