Article Summary & FAQs

What is turbulent flow?

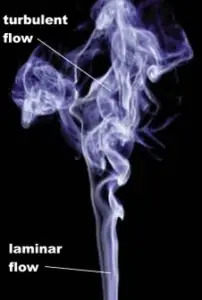

Turbulent flow is characterized by the irregular movement of fluid particles (one can say chaotic). Turbulent flow tends to occur at higher velocities, low viscosity. Detailed knowledge of the behavior of turbulent flow regimes is important in engineering because most industrial flows are turbulent.

Key Facts

- When the viscous forces are dominant (slow flow, low Re), they are sufficient to keep all the fluid particles in line, then the flow is laminar.

- When the inertial forces dominate over the viscous forces (when the fluid flows faster and Re is larger), the flow is turbulent.

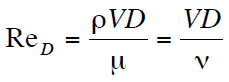

- The Reynolds number is one of the characteristic numbers used for predicting whether a flow condition will be laminar or turbulent. It is defined as the ratio of inertial forces to viscous forces.

in which V is the mean flow velocity, D is a characteristic linear dimension, ρ fluid density, μ dynamic viscosity, and ν kinematic viscosity.

in which V is the mean flow velocity, D is a characteristic linear dimension, ρ fluid density, μ dynamic viscosity, and ν kinematic viscosity. - Turbulent flow occurs at Re > 4000. Usually, a higher velocity flow is required, but this also depends on the size of an object.

- The flow is characterized by the irregular movement of particles of the fluid. Average motion is in the direction of the flow.

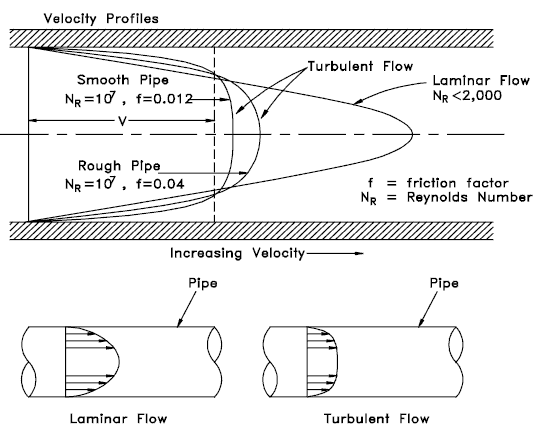

- The flow velocity profile for turbulent flow is fairly flat across the center section of a pipe and drops rapidly extremely close to the walls. The average flow velocity is approximately equal to the velocity at the center of the pipe.

- Mathematical analysis is very difficult. The main tool available for the analysis of turbulent flows is CFD analysis.

In fluid dynamics, turbulent flow is characterized by the irregular movement of fluid particles (one can say chaotic) of the fluid. In contrast to laminar flow, the fluid does not flow in parallel layers, the lateral mixing is very high, and there is a disruption between the layers. Turbulence is also characterized by recirculation, eddies, and apparent randomness. In turbulent flow, the speed of the fluid at a point is continuously undergoing changes in both magnitude and direction.

Detailed knowledge of the behavior of turbulent flow regimes is important in engineering because most industrial flows, especially those in nuclear engineering, are turbulent. Unfortunately, the highly intermittent and irregular character of turbulence complicates all analyses. Turbulence is often said to be the “last unsolved problem in classical mathematical physics.”

The main tool available for their analysis is CFD analysis. CFD is a branch of fluid mechanics that uses numerical analysis and algorithms to solve and analyze problems that involve turbulent fluid flows. It is widely accepted that the Navier–Stokes equations (or simplified Reynolds-averaged Navier–Stokes equations) can exhibit turbulent solutions, and these equations are the basis for essentially all CFD codes.

See also: Internal Flow

See also: External Flow

Characteristics of Turbulent Flow

- Turbulent flow tends to occur at higher velocities, low viscosity, and at higher characteristic linear dimensions.

- If the Reynolds number is greater than Re > 3500, the flow is turbulent.

- Irregularity: The flow is characterized by the irregular movement of particles of the fluid. The movement of fluid particles is chaotic. For this reason, turbulent flow is normally treated statistically rather than deterministically.

- Diffusivity: In turbulent flow, a fairly flat velocity distribution exists across the section of the pipe. The result is that the entire fluid flows at a given single value and drops rapidly, extremely close to the walls. The characteristic responsible for the enhanced mixing and increased rates of mass, momentum, and energy transports in a flow is called “diffusivity”.

- Rotationality: Turbulent flow is characterized by a strong three-dimensional vortex generation mechanism. This mechanism is known as vortex stretching.

- Dissipation: A dissipative process is a process in which the kinetic energy of the turbulent flow is transformed into internal energy by viscous shear stress.

Reynolds Number for Turbulent Flow

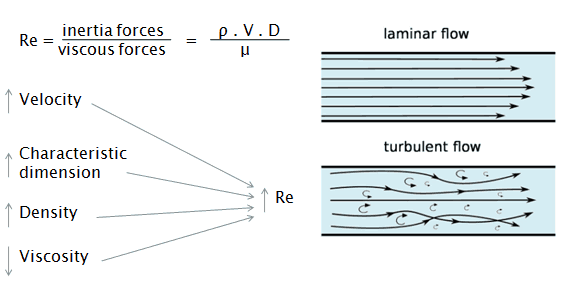

The Reynolds number is the ratio of inertial forces to viscous forces and is a convenient parameter for predicting if a flow condition will be laminar or turbulent. It can be interpreted that when the viscous forces are dominant (slow flow, low Re), they are sufficient enough to keep all the fluid particles in line, then the flow is laminar. Even very low Re indicates viscous creeping motion, where inertia effects are negligible. When the inertial forces dominate over the viscous forces (when the fluid flows faster and Re is larger), the flow is turbulent.

It is a dimensionless number comprised of the physical characteristics of the flow. An increasing Reynolds number indicates increasing turbulence of flow.

where:

V is the flow velocity,

D is a characteristic linear dimension (traveled length of the fluid; hydraulic diameter etc.)

ρ fluid density (kg/m3),

μ dynamic viscosity (Pa.s),

ν kinematic viscosity (m2/s); ν = μ / ρ.

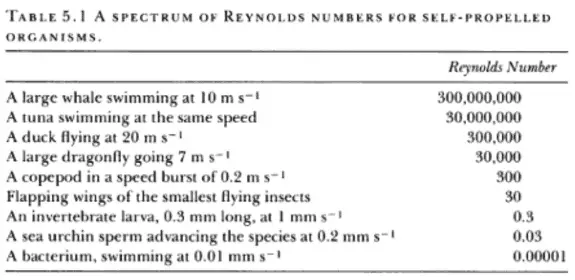

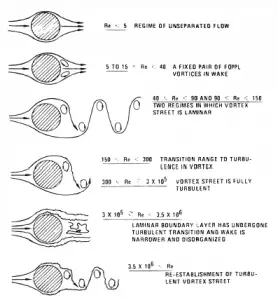

Source: Blevins, R. D. (1990), Flow-Induced Vibration, 2nd Edn., Van Nostrand Reinhold Co.

- Laminar flow. For practical purposes, if the Reynolds number is less than 2000, the flow is laminar. The accepted transition Reynolds number for flow in a circular pipe is Red,crit = 2300.

- Transitional flow. At Reynolds numbers between about 2000 and 4000, the flow is unstable due to the onset of turbulence. These flows are sometimes referred to as transitional flows.

- Turbulent flow. If the Reynolds number is greater than 3500, the flow is turbulent. Most fluid systems in nuclear facilities operate with turbulent flow.

Turbulent Velocity Profile

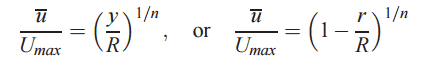

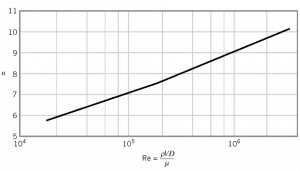

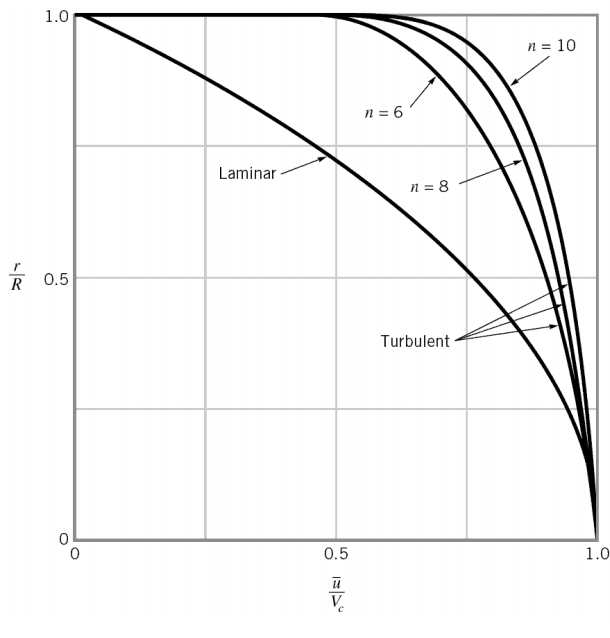

Power-law velocity profile – Turbulent velocity profile

The velocity profile in turbulent flow is flatter in the central part of the pipe (i.e., in the turbulent core) than in laminar flow. The flow velocity drops rapidly, extremely close to the walls. This is due to the diffusivity of the turbulent flow.

The velocity profile in turbulent flow is flatter in the central part of the pipe (i.e., in the turbulent core) than in laminar flow. The flow velocity drops rapidly, extremely close to the walls. This is due to the diffusivity of the turbulent flow.

In the case of turbulent pipe flow, there are many empirical velocity profiles. The simplest and the best known is the power-law velocity profile:

where the exponent n is a constant whose value depends on the Reynolds number. This dependency is empirical, and it is shown in the picture. In short, the value n increases with increasing Reynolds number. The one-seventh power-law velocity profile approximates many industrial flows.

Examples of Turbulent Flow

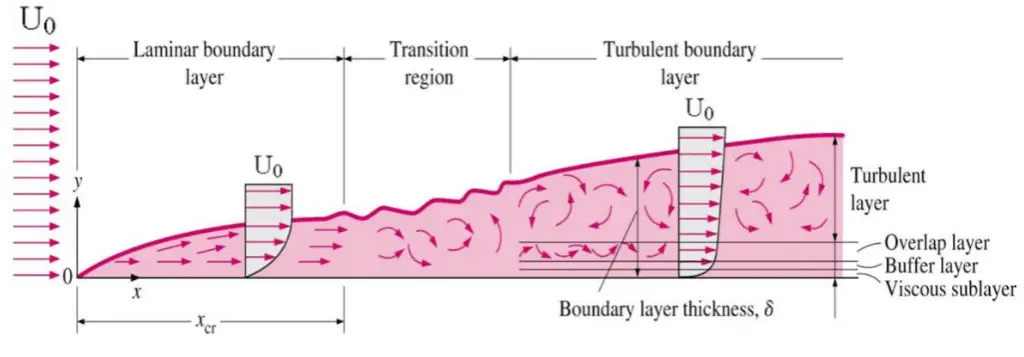

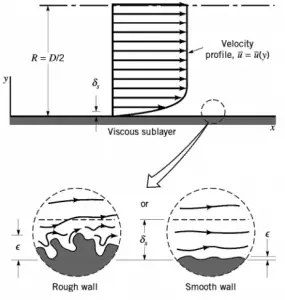

Turbulent Boundary Layer

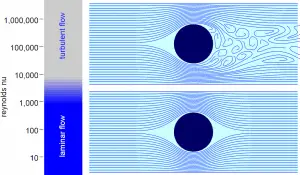

The concept of boundary layers is important in all viscous fluid dynamics, aerodynamics, and heat transfer theory. Basic characteristics of all laminar and turbulent boundary layers are shown in the developing flow over a flat plate. The stages of the formation of the boundary layer are shown in the figure below:

Boundary layers may be either laminar or turbulent, depending on the value of the Reynolds number. Also, here the Reynolds number represents the ratio of inertia forces to viscous forces and is a convenient parameter for predicting if a flow condition will be laminar or turbulent. It is defined as:

in which V is the mean flow velocity, D is a characteristic linear dimension, ρ fluid density, μ dynamic viscosity, and ν kinematic viscosity.

The boundary layer is laminar for lower Reynolds numbers, and the streamwise velocity uniformly changes as one moves away from the wall, as shown on the left side of the figure. As the Reynolds number increases (with x), the flow becomes unstable. Finally, the boundary layer is turbulent for higher Reynolds numbers, and the streamwise velocity is characterized by unsteady (changing with time) swirling flows inside the boundary layer.

The transition from laminar to turbulent boundary layer occurs when Reynolds number at x exceeds Rex ~ 500,000. The transition may occur earlier, but it is dependent especially on the surface roughness. The turbulent boundary layer thickens more rapidly than the laminar boundary layer due to increased shear stress at the body surface.

See also: Boundary layer thickness.

See also: Tube in cross-flow – external flow.

Special reference: Schlichting Herrmann, Gersten Klaus. Boundary-Layer Theory, Springer-Verlag Berlin Heidelberg, 2000, ISBN: 978-3-540-66270-9

Pressure Loss Calculation

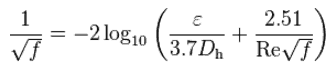

The most common method to determine a friction factor for turbulent flow is to use the Moody chart. The Moody chart (also known as the Moody diagram) is a log-log plot of the Colebrook correlation that relates the Darcy friction factor, Reynolds number, and the relative roughness for fully developed flow in a circular pipe. The Colebrook–White equation:

which is also known as the Colebrook equation, expresses the Darcy friction factor f as a function of pipe relative roughness ε / Dh and Reynolds number.

In 1939, Colebrook found an implicit correlation for the friction factor in round pipes by fitting the experimental studies of turbulent flow in smooth and rough pipes.

For hydraulically smooth pipe and the turbulent flow (Re < 105), the friction factor can be approximated by the Blasius formula:

f = (100.Re)-¼

It must be noted that the friction factor is independent of the Reynolds number at very large Reynolds numbers. This is because the thickness of the laminar sublayer (viscous sublayer) decreases with increasing Reynolds number. For very large Reynolds numbers, the thickness of the laminar sublayer is comparable to the surface roughness, and it directly influences the flow. The laminar sublayer becomes so thin that the surface roughness protrudes into the flow. The frictional losses, in this case, are produced in the main flow primarily by the protruding roughness elements, and the contribution of the laminar sublayer is negligible.

It must be noted that the friction factor is independent of the Reynolds number at very large Reynolds numbers. This is because the thickness of the laminar sublayer (viscous sublayer) decreases with increasing Reynolds number. For very large Reynolds numbers, the thickness of the laminar sublayer is comparable to the surface roughness, and it directly influences the flow. The laminar sublayer becomes so thin that the surface roughness protrudes into the flow. The frictional losses, in this case, are produced in the main flow primarily by the protruding roughness elements, and the contribution of the laminar sublayer is negligible.

Heat Transfer Coefficient

External Turbulent Flow

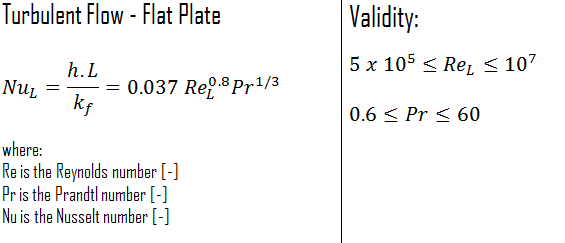

The average Nusselt number over the entire plate is determined by:

This relation gives the average heat transfer coefficient for the entire plate only when the flow is turbulent over the entire plate or when the laminar flow region of the plate is too small relative to the turbulent flow region.

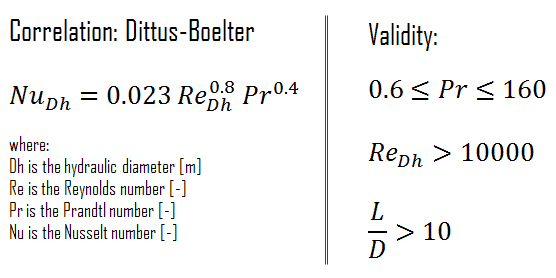

Internal Turbulent Flow – Dittus-Boelter

See also: Dittus-Boelter Equation.

For fully developed (hydrodynamically and thermally) turbulent flow in a smooth circular tube, the local Nusselt number may be obtained from the well-known Dittus-Boelter equation. The DittusBoelter equation is easy to solve. Still, it is less accurate when there is a large temperature difference across the fluid and is less accurate for rough tubes (many commercial applications) since it is tailored to smooth tubes.

The Dittus-Boelter correlation may be used for small to moderate temperature differences, Twall – Tavg, with all properties evaluated at an, averaged temperature Tavg.

For flows characterized by large property variations, the corrections (e.g.,, a viscosity correction factor μ/μwall) must be considered, for example, as Sieder and Tate recommend.

Kolmogorov Microscales

In the view of Kolmogorov (Andrey Nikolaevich Kolmogorov was a Russian mathematician who made significant contributions to the mathematics of probability theory and turbulence), turbulent motions involve a wide range of scales. From a macroscale at which the energy is supplied to a microscale at which energy is dissipated by viscosity.

For example, consider a cumulus cloud. The macroscale of the cloud can be of the order of kilometers and may grow or persist over long periods of time. Within the cloud, eddies may occur over scales of the order of millimeters. For smaller flows such as in pipes, the microscales may be much smaller. Most of the kinetic energy of the turbulent flow is contained in the macroscale structures. The energy “cascades” from these macroscale structures to microscale structures by an inertial mechanism. This process is known as the turbulent energy cascade.

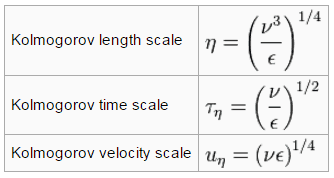

The smallest scales in turbulent flow are known as the Kolmogorov microscales. These are small enough that molecular diffusion becomes important and viscous dissipation of energy occurs, and the turbulent kinetic energy is dissipated into heat.

The smallest scales in turbulent flow, i.e., the Kolmogorov microscales, are:

where ε is the average rate of the dissipation rate of turbulence kinetic energy per unit mass and has dimensions (m2/s3). ν is the kinematic viscosity of the fluid and has dimensions (m2/s).

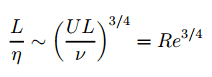

The size of the smallest eddy in the flow is determined by viscosity. The Kolmogorov length scale decreases as viscosity decreases. For very high Reynolds number flows, the viscous forces are smaller with respect to inertial forces. Smaller-scale motions are then necessarily generated until the effects of viscosity become important, and energy is dissipated. The largest to smallest length scales ratio in the turbulent flow is proportional to the Reynolds number (raises with the three-quarters power).

This causes direct numerical simulations of turbulent flow to be practically impossible. For example, consider a flow with a Reynolds number of 106. In this case, the ratio L/l is proportional to 1018/4. Since we have to analyze the three-dimensional problem, we need to compute a grid that consists of at least 1014 grid points. This far exceeds the capacity and possibilities of existing computers.