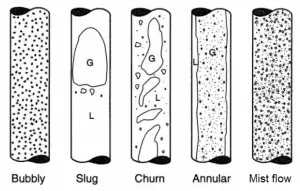

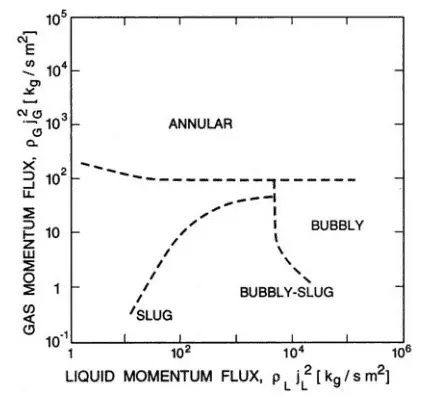

Annular Flow – Vertical Tubes

Annular flow is a flow regime of two-phase gas-liquid flow. It is characterized by the presence of a liquid film flowing on the channel wall (forming an annular ring of liquid) while the gas flows as a continuous phase up in the center of the tube. The flow core can contain entrained liquid droplets. The velocity of the gas core is very large, and it is large enough to cause high-frequency waves and ripples at the interface. This flow regime is particularly stable, and it is desired flow regime for high-velocity, high-quality two-phase fluid flow.

Both adiabatic annular flows (without heat exchange) and diabatic annular flows (with heat exchange) occur in industrial applications:

- in steam generators

- condensers

- boiling water reactors – BWR

- during accidents in PWRs

In the case of BWR, in which a phase transition (evaporation) occurs, detailed knowledge of this flow regime is highly important. At given combinations of flow rate through a channel, pressure, flow quality, and linear heat rate, the liquid wall film may exhaust, and the wall may be dried out. This phenomenon is usually known as “dry-out”. Dryout is accompanied by a rapid rise in wall temperature and is important in the safety of BWRs.

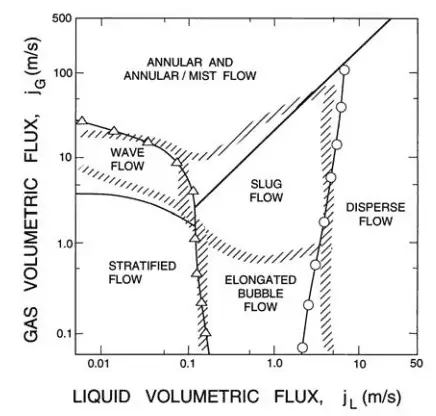

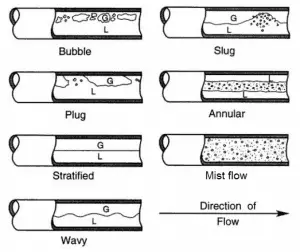

Annular Flow – Horizontal Tubes

Similar to vertical flow, the liquid forms a continuous annular film on the channel wall at larger gas flow velocities. The horizontal annular flow is characterized by the presence of a thicker liquid film flowing on the bottom of the channel wall. The gas flows as a continuous phase in the center of the tube. The flow core can contain entrained liquid droplets. The velocity of the gas core is very large, and it is large enough to cause high-frequency waves and ripples at the interface. This flow regime is particularly stable, and it is desired flow regime for high-velocity, high-quality two-phase fluid flow.