The flow regime can be also classified according to the geometry of a conduit or flow area. From this point of view, we distinguish:

Internal flow is a flow for which the fluid is confined by a surface. Detailed knowledge of the behavior of internal flow regimes is important in engineering because circular pipes can withstand high pressures and hence are used to convey liquids. On the other hand, external flow is such a flow in which boundary layers develop freely, without constraints imposed by adjacent surfaces. Detailed knowledge of the behavior of external flow regimes is important, especially in aeronautics and aerodynamics.

External Flow

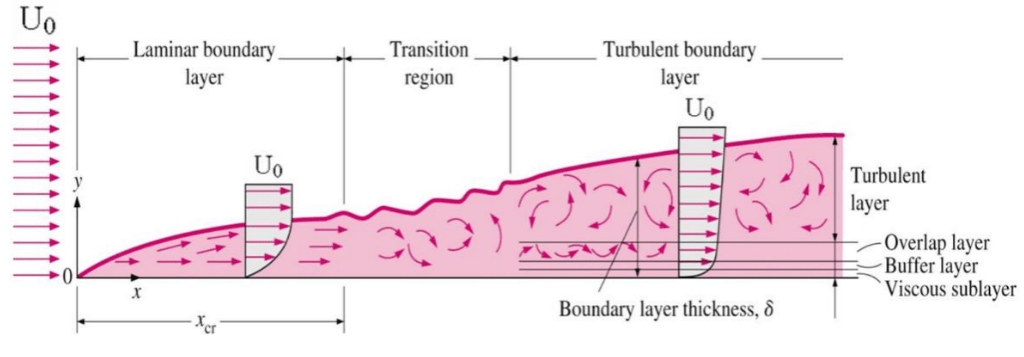

In fluid dynamics, external flow is a flow in which boundary layers develop freely, without constraints imposed by adjacent surfaces. In comparison to internal flow, external flows feature highly viscous effects confined to rapidly growing “boundary layers” in the entrance region or thin shear layers along the solid surface. Accordingly, there will always exist a region of the flow outside the boundary layer. In this region, velocity, temperature, and/or concentration do not change, and their gradients may be neglected.

This effect causes the boundary layer to be expanding, and the boundary-layer thickness relates to the fluid’s kinematic viscosity.

This is demonstrated in the following picture. Far from the body, the flow is nearly inviscid, and it can be defined as the flow of a fluid around a body that is completely submerged in it.

External Flow – Flat Plate

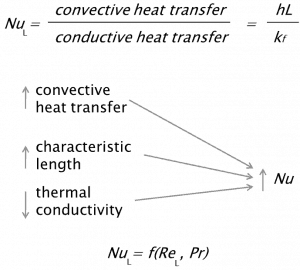

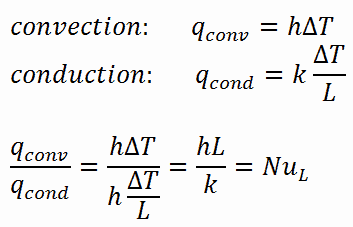

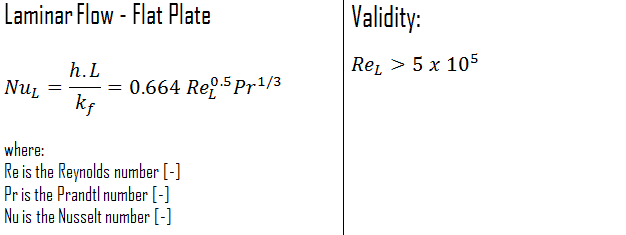

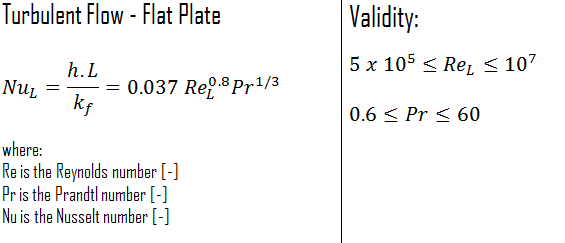

The average Nusselt number over the entire plate is determined by:

This relation gives the average heat transfer coefficient for the entire plate when the flow is laminar over the entire plate.

This relation gives the average heat transfer coefficient for the entire plate only when the flow is turbulent over the entire plate, or when the laminar flow region of the plate is too small relative to the turbulent flow region.

Internal Flow

In fluid dynamics, internal flow is a flow for which the fluid is confined by a surface. Detailed knowledge of the behavior of internal flow regimes is important in engineering because circular pipes can withstand high pressures and hence are used to convey liquids. Non-circular ducts are used to transport low-pressure gases, such as air in cooling and heating systems. The internal flow configuration is a convenient geometry for heating and cooling fluids used in energy conversion technologies such as nuclear power plants.

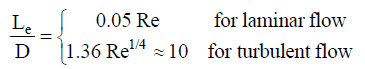

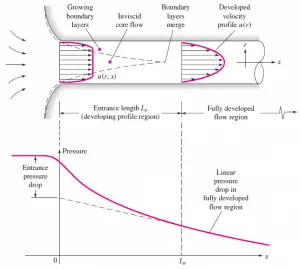

An entrance region is typical for the internal flow regime, and a nearly inviscid upstream flow converges and enters the tube in this region. To characterize this region, the hydrodynamic entrance length is introduced and is approximately equal to:

The maximum hydrodynamic entrance length, at ReD,crit = 2300 (laminar flow), is Le = 138d, where D is the diameter of the pipe. This is the longest development length possible. The boundary layers grow faster in turbulent flow, and Le is relatively shorter. For any given problem, Le / D has to be checked to see if Le is negligible compared to the pipe length. The entrance effects may be neglected at a finite distance from the entrance because the boundary layers merge and the inviscid core disappears. The tube flow is then fully developed.

Internal Laminar Flow – Nusselt Number

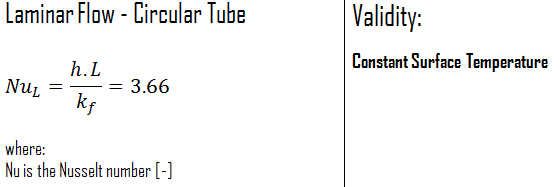

Constant Surface Temperature

In laminar flow in a tube with constant surface temperature, both the friction factor and the heat transfer coefficient remain constant in the fully developed region.

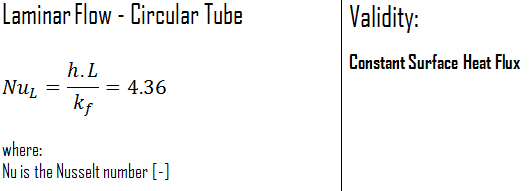

Constant Surface Heat Flux

Therefore, for fully developed laminar flow in a circular tube subjected to constant surface heat flux, the Nusselt number is a constant. There is no dependence on the Reynolds or the Prandtl numbers.

Internal Turbulent Flow – Nusselt Number

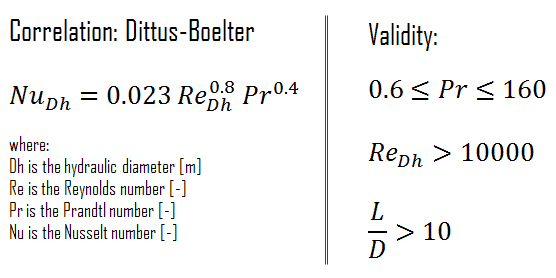

See also: Dittus-Boelter Equation

For fully developed (hydrodynamically and thermally) turbulent flow in a smooth circular tube, the local Nusselt number may be obtained from the well-known Dittus-Boelter equation. The DittusBoelter equation is easy to solve. Still, it is less accurate when there is a large temperature difference across the fluid and is less accurate for rough tubes (many commercial applications) since it is tailored to smooth tubes.

The Dittus-Boelter correlation may be used for small to moderate temperature differences, Twall – Tavg, with all properties evaluated at an, averaged temperature Tavg.

For flows characterized by large property variations, the corrections (e.g., a viscosity correction factor μ/μwall) must be taken into account, for example, as Sieder and Tate recommend.

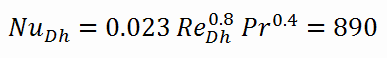

Calculation of the Nusselt number using Dittus-Boelter equation

For fully developed (hydrodynamically and thermally) turbulent flow in a smooth circular tube, the local Nusselt number may be obtained from the well-known DittusBoelter equation.

To calculate the Nusselt number, we have to know:

- the Reynolds number, which is ReDh = 575600

- the Prandtl number, which is Pr = 0.89

The Nusselt number for the forced convection inside the fuel channel is then equal to: