The Dittus-Boelter correlation may be used for small to moderate temperature differences, Twall – Tavg, with all properties evaluated at an, averaged temperature Tavg.

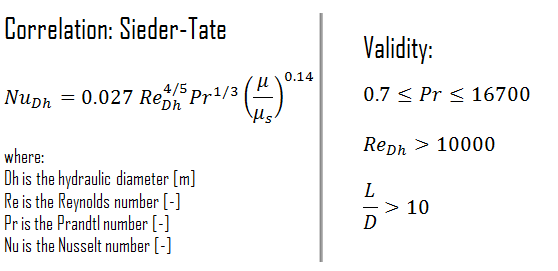

For flows characterized by large property variations, the corrections (e.g., a viscosity correction factor μ/μwall) must be considered, for example, as Sieder and Tate recommend.

When the difference between the surface and the fluid temperatures is large, it may be necessary to account for the viscosity variation with temperature. Therefore a modified form of the Dittus-Boelter equation was proposed by Sieder and Tate (1936).

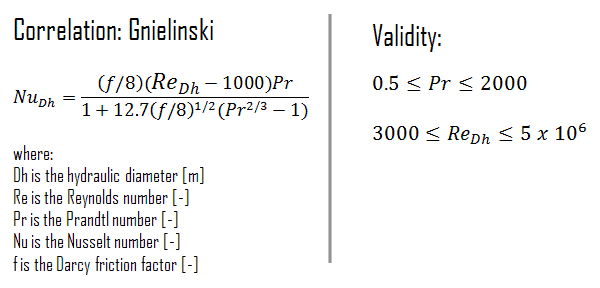

Gnielinski Equation

Although the Dittus-Boelter and Sieder-Tate equations are easily applied and are certainly satisfied for the purposes of this article, errors as large as 25% may result from their use. Such errors may be reduced by using more recent but generally more complex correlations such as the Gnielinski correlation. This equation validates tubes over a large Reynolds number range, including the transition region.

The Darcy friction factor, f, is a dimensionless quantity used in the Darcy–Weisbach equation for the description of frictional losses in pipe or duct as well as for open-channel flow. This is also called the Darcy–Weisbach friction factor, resistance coefficient, or simply friction factor.

Rough-walled Tubes

We also note that all these equations pertain to smooth tubes. The heat transfer coefficient increases with wall roughness for turbulent flow in rough tubes. As the Reynolds number increases, the viscous sublayer becomes thinner and smaller. The viscous sublayer becomes so thin that the surface roughness protrudes into the flow at a very high Reynolds number. The frictional losses, in this case, are produced in the main flow primarily by the protruding roughness elements, and the contribution of the laminar sublayer is negligible.

Special Reference: A Heat Transfer Textbook, John H. Lienhard IV and John H. Lienhard V. Phlogiston Press, 2012.