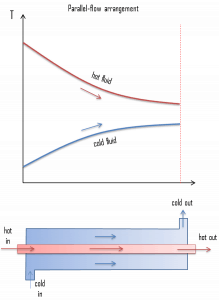

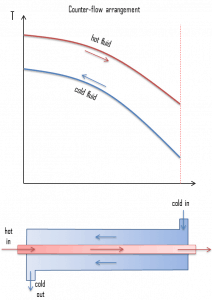

Heat exchangers are typically classified according to flow arrangement and type of construction. The simplest heat exchanger is one for which the hot and cold fluids move in the same or opposite directions, and this heat exchanger consists of two concentric pipes of different diameters.

- parallel-flow arrangement. In the parallel-flow arrangement, the hot and cold fluids enter at the same end, flow in the same direction, and leave at the same end.

- counter-flow arrangement. In the counter-flow arrangement, the fluids enter at opposite ends, flow in opposite directions, and leave at opposite ends.

The figure represents fluid flow directions in the parallel and counter-flow exchangers. Under comparable conditions, more heat is transferred in a counter-flow arrangement than in a parallel flow heat exchanger. The temperature profiles of the two heat exchangers indicate two major disadvantages in the parallel-flow design.

- The large temperature difference at the ends causes large thermal stresses.

- The temperature of the cold fluid exiting the heat exchanger never exceeds the lowest temperature of the hot fluid.

The design of a parallel flow heat exchanger is advantageous when two fluids are required to be brought to nearly the same temperature.