Insulation Materials

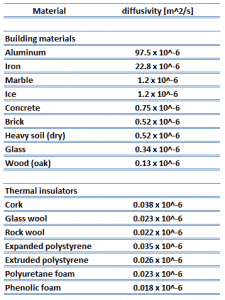

As was written, thermal insulation is based on the use of substances with very low thermal conductivity. These materials are known as insulation materials. Common insulation materials are wool, fiberglass, rock wool, polystyrene, polyurethane, goose feather, etc. Therefore, these materials are very poor conductors of heat and are good thermal insulators.

As was written, thermal insulation is based on the use of substances with very low thermal conductivity. These materials are known as insulation materials. Common insulation materials are wool, fiberglass, rock wool, polystyrene, polyurethane, goose feather, etc. Therefore, these materials are very poor conductors of heat and are good thermal insulators.

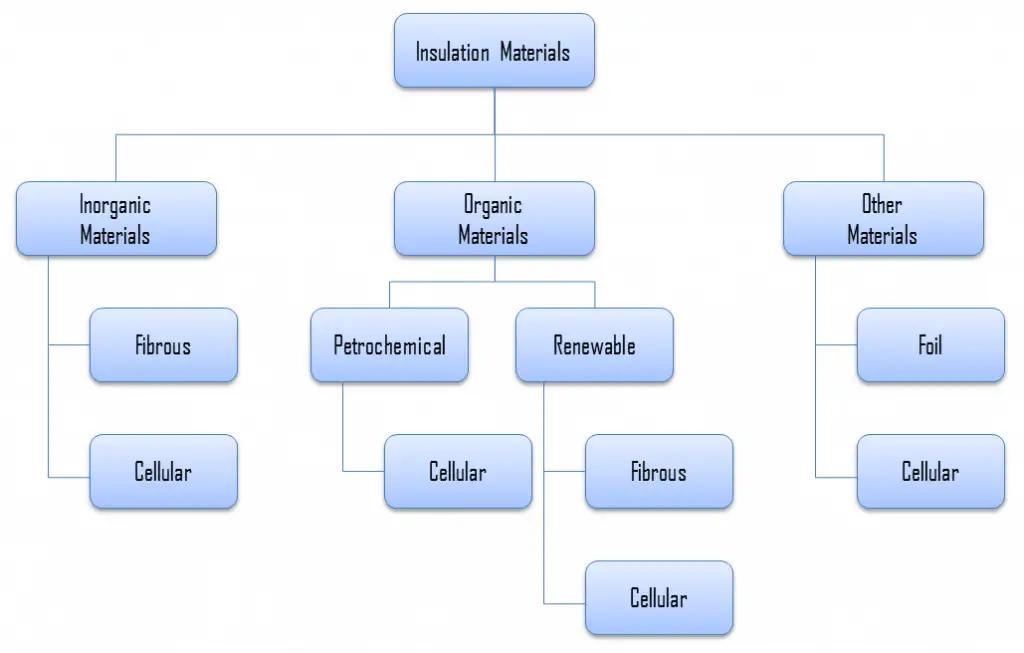

Types of Insulation – Categorization of Insulation Materials

For insulation materials, three general categories can be defined. These categories are based on the chemical composition of the base material from which the insulating material is produced.

In further reading, there is a brief description of these types of insulation materials.

Inorganic Insulation Materials

As can be seen from the figure, inorganic materials can be classified accordingly:

- Fibrous materials

- Cellular materials

- Calcium silicate

- Cellular glass

Example of Insulation – Glass Wool

Glass wool (originally known also as fiberglass) is an insulating material made from fibers of glass arranged using a binder into a texture similar to wool. Glass wool and stone wool is produced from mineral fibers and are therefore often referred to as ‘mineral wools’. Mineral wool is a general name for fiber materials formed by spinning or drawing molten minerals. Glass wool is a furnace product of molten glass at a temperature of about 1450 °C. From the melted glass, fibers are spun. This process is based on spinning molten glass in high-speed spinning heads, somewhat like the process used to produce cotton candy. A binding agent is injected during the spinning of the glass fibers. Glass wool is then produced in rolls or slabs, with different thermal and mechanical properties. It may also be produced as a material that can be sprayed or applied in place on the surface to be insulated.

Glass wool (originally known also as fiberglass) is an insulating material made from fibers of glass arranged using a binder into a texture similar to wool. Glass wool and stone wool is produced from mineral fibers and are therefore often referred to as ‘mineral wools’. Mineral wool is a general name for fiber materials formed by spinning or drawing molten minerals. Glass wool is a furnace product of molten glass at a temperature of about 1450 °C. From the melted glass, fibers are spun. This process is based on spinning molten glass in high-speed spinning heads, somewhat like the process used to produce cotton candy. A binding agent is injected during the spinning of the glass fibers. Glass wool is then produced in rolls or slabs, with different thermal and mechanical properties. It may also be produced as a material that can be sprayed or applied in place on the surface to be insulated.

Applications of glass wool include structural insulation, pipe insulation, filtration, and soundproofing. Glass wool is a versatile material that can be used for the insulation of walls, roofs, and floors. It can be a loose-fill material, blown into attics, or, together with an active binder sprayed on the underside of structures. During the installation of the glass wool, it should be kept dry at all times since an increase in the moisture content causes a significant increase in thermal conductivity.