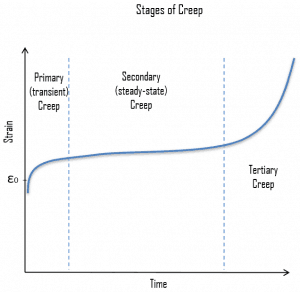

Creep, also known as cold flow, is the permanent deformation that increases with time under constant load or stress. It results from long-time exposure to large external mechanical stress within the limit of yielding and is more severe in materials subjected to heat for a long time. The rate of deformation is a function of the material’s properties, exposure time, exposure temperature, and the applied structural load. Creep is very important if we use materials at high temperatures. Creep is very important in the power industry and is of the highest importance in designing jet engines. Time to rupture is the dominant design consideration for many relatively short-life creep situations (e.g., turbine blades in military aircraft). Of course, for its determination, creep tests must be conducted to the point of failure, termed creep rupture tests.

Creep Prevention – Creep Resistance

Creep prevention is based on the proper choice of material is also crucial. The creep resistance of materials can be influenced by many factors such as diffusivity, precipitate, and grain size. In general, there are three general ways to prevent creep in metal. One way is to use higher melting point metals, the second is to use materials with greater grain size, and the third is to use alloying. Body-centered cubic (BCC) metals are less creep resistant in high temperatures. Therefore, superalloys (typically face-centered cubic austenitic alloys) based on Co, Ni, and Fe can be engineered to be highly resistant to creep and have thus arisen as an ideal material in high-temperature environments.

Operating the device within limits is of the highest importance for devices of selected material, especially regarding maximum service temperature and stress. The rate of creep is highly dependent on both stress and temperature. With most engineering alloys used in construction at room temperature or lower, creep strain is so small at working loads that it can safely be ignored. However, as temperature rises, creep becomes progressively more important and eventually supersedes fatigue as the likely criterion for failure. The temperature at which creep becomes important will vary with the material. For safe operation, the total deformation due to creep must be well below the strain at which failure occurs.