Indentation hardness measures the ability to withstand surface indentation (localized plastic deformation) and the resistance of a sample to material deformation due to a constant compression load from a sharp object. Tests for indentation hardness are primarily used in engineering and metallurgy fields. The traditional methods are based on well-defined physical indentation hardness tests. Very hard indenters of defined geometries and sizes are continuously pressed into the material under a particular force. Deformation parameters, such as the indentation depth in the Rockwell method, are recorded to give measures of hardness. Common indentation hardness scales are Brinell, Rockwell and Vickers.

See also: Hardness

Knoop Hardness Test

The Knoop hardness test method is one of the microhardness tests – tests for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. The Knoop and Vickers techniques are called micro-indentation-testing methods based on indenter size. Both are well suited for measuring the hardness of small, selected specimen regions; furthermore, the Knoop technique is used for testing brittle materials such as ceramics. The geometry of this indenter is an extended pyramid with the length to width ratio being 7:1, and respective face angles are 172 degrees for the long edge and 130 degrees for the short edge.

The Knoop hardness test method is one of the microhardness tests – tests for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. The Knoop and Vickers techniques are called micro-indentation-testing methods based on indenter size. Both are well suited for measuring the hardness of small, selected specimen regions; furthermore, the Knoop technique is used for testing brittle materials such as ceramics. The geometry of this indenter is an extended pyramid with the length to width ratio being 7:1, and respective face angles are 172 degrees for the long edge and 130 degrees for the short edge.

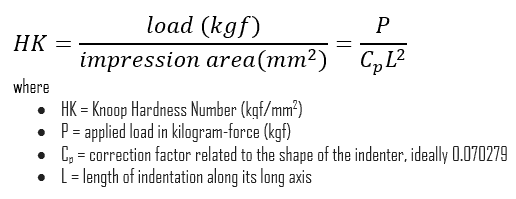

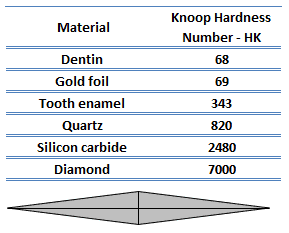

The Knoop and Vickers hardness numbers are designated by HK and HV, respectively, and hardness scales for both techniques are approximately equivalent. The Knoop hardness number HK is given by the formula:

See also: Brinell Hardness Test

See also: Rockwell Hardness Test

See also: Vickers Hardness Test