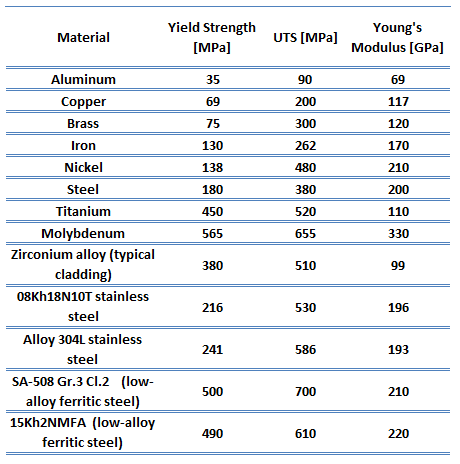

Young’s modulus of elasticity is the elastic modulus for tensile and compressive stress in the linear elasticity regime of a uniaxial deformation and is usually assessed by tensile tests. Young’s modulus is named after the 19th-century British scientist Thomas Young.

Young’s modulus of elasticity is the elastic modulus for tensile and compressive stress in the linear elasticity regime of a uniaxial deformation and is usually assessed by tensile tests. Young’s modulus is named after the 19th-century British scientist Thomas Young.

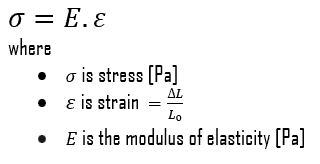

Most polycrystalline materials have an almost constant relationship between stress and strain within their elastic range. In 1678 an English scientist named Robert Hooke ran experiments that provided data showing that strain is proportional to stress in the elastic range of material. Robert Hooke concluded that the force F in any spring is proportional to the extension (the deformation from the relaxed state) x as follows:

F = k · x

where the term k is the stiffness of the spring and x is small compared to the total possible deformation of the spring. It must eventually fail once the forces exceed some limit since no material can be compressed beyond a certain minimum size or stretched beyond a maximum size without permanent deformation or change of state.

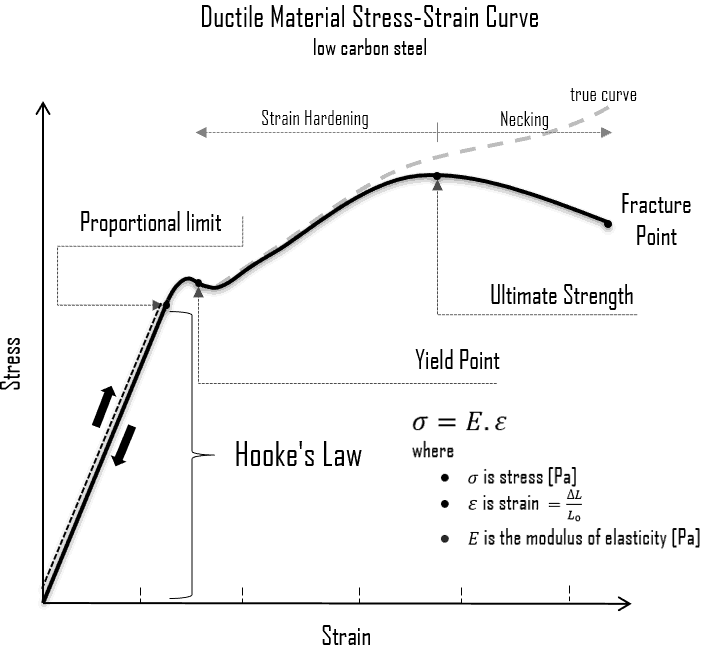

Hooke’s law describes the behavior of a bar in the elastic region in the case of tensional stress of a uniform bar (stress-strain curve). In this region, the elongation of the bar is directly proportional to the tensile force and the length of the bar and inversely proportional to the cross-sectional area and the modulus of elasticity. Up to limiting stress, a body will be able to recover its dimensions on the removal of the load. The applied stresses cause the atoms in a crystal to move from their equilibrium position, and all the atoms are displaced the same amount and maintain their relative geometry. When the stresses are removed, all the atoms return to their original positions, and no permanent deformation occurs. According to Hooke’s law, the stress is proportional to the strain (in the elastic region), and the slope is Young’s modulus. Young’s modulus is equal to the longitudinal stress divided by the strain.

The elastic moduli relevant to polycrystalline materials:

Young’s Modulus of Elasticity. Young’s modulus of elasticity is the elastic modulus for tensile and compressive stress in the linear elasticity regime of a uniaxial deformation and is usually assessed by tensile tests. Young’s modulus is named after the 19th-century British scientist Thomas Young.

Young’s Modulus of Elasticity. Young’s modulus of elasticity is the elastic modulus for tensile and compressive stress in the linear elasticity regime of a uniaxial deformation and is usually assessed by tensile tests. Young’s modulus is named after the 19th-century British scientist Thomas Young.- Shear Modulus of Elasticity. The shear modulus, or the modulus of rigidity, is derived from the torsion of a cylindrical test piece, describing the material’s response to shear stress. Its symbol is G. The shear modulus is one of several quantities for measuring the stiffness of materials, and it arises in the generalized Hooke’s law.

- Bulk Modulus of Elasticity. The bulk modulus of elasticity describes volumetric elasticity, or the tendency of an object to deform in all directions when uniformly loaded in all directions. For example, it describes the elastic response to hydrostatic pressure and equilateral tension (like the pressure at the bottom of the ocean or a deep swimming pool). It is also the property of a material that determines the elastic response to applying stress. For a fluid, only the bulk modulus is meaningful.