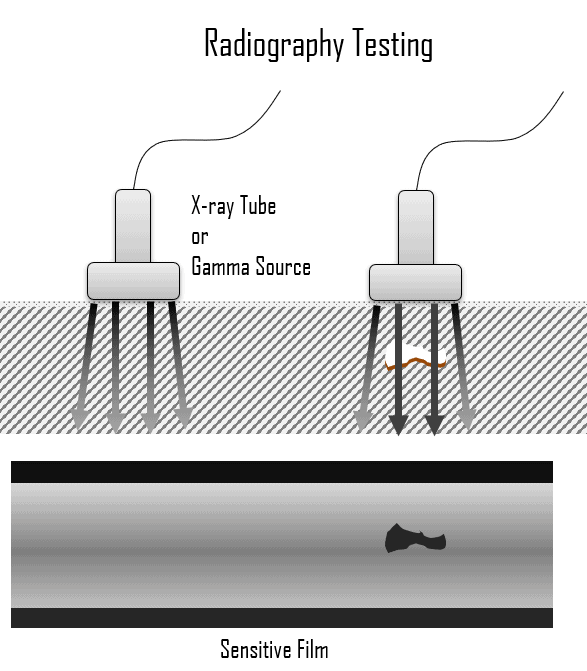

In general, RT is a method of inspecting materials for hidden subsurface defects by using the ability of X-rays or gamma rays to penetrate various materials of various thicknesses. The intensity of the radiation that penetrates and passes through the material is either captured by:

- a radiation-sensitive film (Film Radiography)

- a planer array of radiation-sensitive sensors (Real-time Radiography).

Principle of Operation

The radiation source can either be an X-ray machine or a radioactive source (Ir-192, Co-60, or in rare cases, Cs-137). The choice between X-rays and gamma radiation depends on factors such as thickness, contrast level, etc. For example, X-rays typically work with less energy than gamma rays, and the thickness is another parameter that influences the results. For example, at thicknesses more than 50 mm, the use of gamma rays increases significantly.

The radiation source can either be an X-ray machine or a radioactive source (Ir-192, Co-60, or in rare cases, Cs-137). The choice between X-rays and gamma radiation depends on factors such as thickness, contrast level, etc. For example, X-rays typically work with less energy than gamma rays, and the thickness is another parameter that influences the results. For example, at thicknesses more than 50 mm, the use of gamma rays increases significantly.

Radiation is directed through a part and onto film or other imaging media, and the resulting radiograph shows the dimensional features of the part. In X-rays and gamma radiation, the darker the film becomes on the image produced as the radiation passes more through the material. On the contrary, the more the ray is absorbed by the material, the lighter the image in those spots. Therefore, possible imperfections are indicated as density changes on the film in the same manner as a medical X-ray shows broken bones.

Radiographic testing is commonly used for weld verification in various industrial applications. In manufacturing, welds are commonly used to join two or more metal parts. The effects of welding on the material surrounding the weld can be detrimental —depending on the materials used and the heat input of the welding process used. The HAZ can be of varying size and strength. For example, the base metal must reach a certain temperature during the welding process, must cool at a specific rate, and must be welded with compatible materials, or the joint may not be strong enough to hold the parts together, or cracks may form in the weld causing it to fail. Defects usually encountered include incomplete penetration, incomplete fusion, undercutting, porosity, and longitudinal cracking. These defects could cause a structure to break or a pipeline to rupture. Welds may be tested using NDT techniques such as industrial radiography or industrial CT scanning using X-rays or gamma rays, ultrasonic testing, liquid penetrant testing, magnetic particle inspection, or via eddy current.

Advantages and Disadvantages

Advantages:

- It has very few material limitations.

- Detection of internal defects for thick materials (e.g., pipelines).

- Minimal or no part preparation is required.

- One of the major advantages of RT is its documentation capability, and RT provides images of the object under inspection.

- The probability of misinterpretation of results is minimized since multiple operators can review each image.

Disadvantages:

- The impact of radiation on health and the environment can be considered one of the major disadvantages of radiographic testing since a few seconds of radiation exposure can result in severe injuries.

- A high degree of skill and experience is required for exposure and interpretation.

- The high voltage needed to create X-rays is dangerous for human health also.

- It is quite an expensive method.

- Ineffective for planar defects and surface defects.