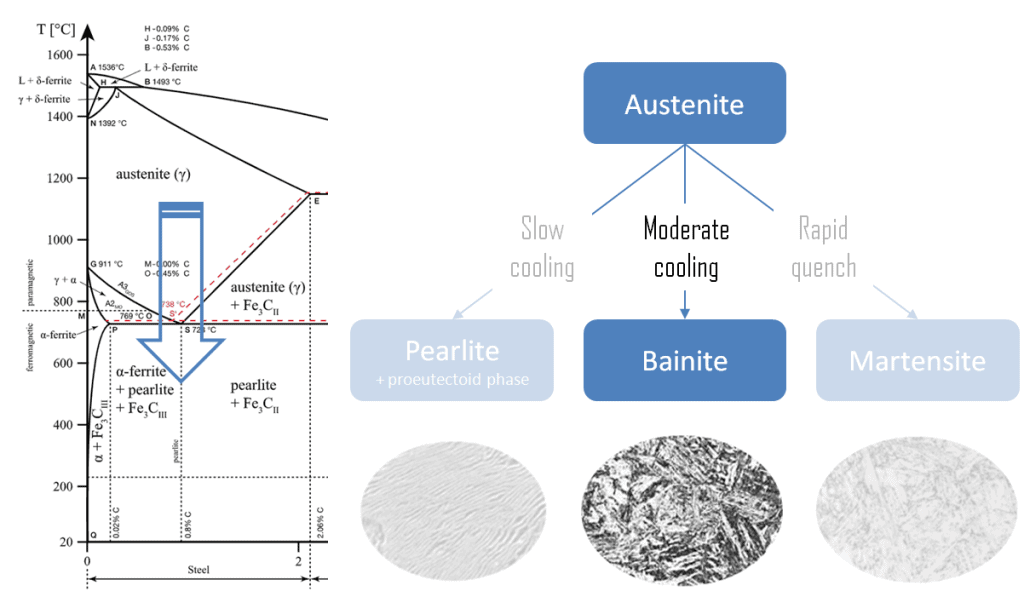

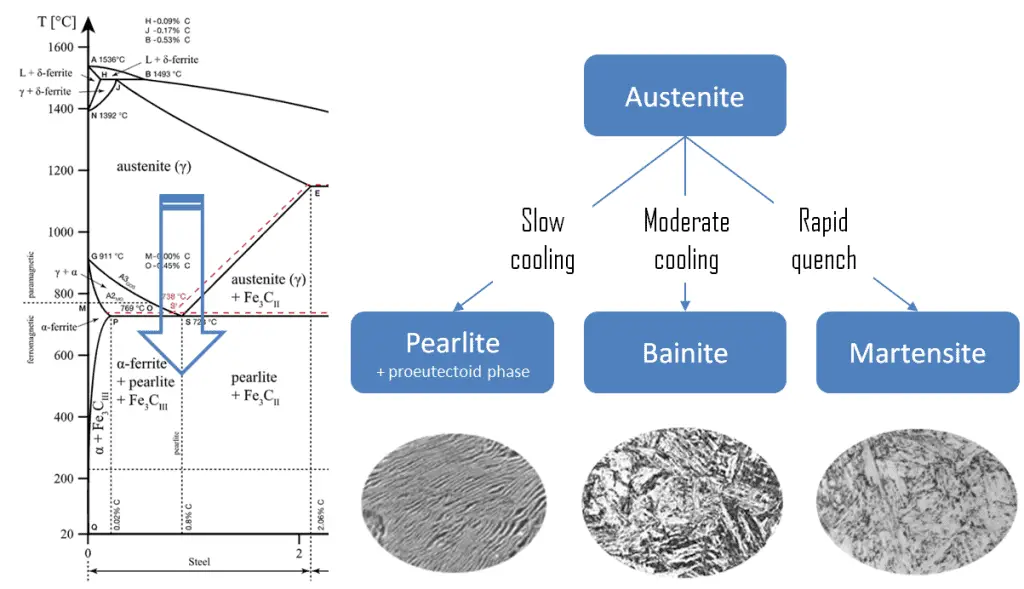

Bainite is a plate-like microstructure that forms in steels from austenite when cooling rates are not rapid enough to produce martensite but are still fast enough so that carbon does not have enough time to diffuse to form pearlite. Like pearlite, the constituent phases of bainite are ferrite and cementite. Diffusional processes during cooling are involved in its formation. However, the shapes of the phases are very different in pearlite and bainite. The key difference between pearlite and bainite is that pearlite contains alternating layers of ferrite and cementite, whereas bainite has a plate-like microstructure.

Bainite is a plate-like microstructure that forms in steels from austenite when cooling rates are not rapid enough to produce martensite but are still fast enough so that carbon does not have enough time to diffuse to form pearlite. Like pearlite, the constituent phases of bainite are ferrite and cementite. Diffusional processes during cooling are involved in its formation. However, the shapes of the phases are very different in pearlite and bainite. The key difference between pearlite and bainite is that pearlite contains alternating layers of ferrite and cementite, whereas bainite has a plate-like microstructure.

A fine non-lamellar structure, bainite commonly consists of cementite and dislocation-rich ferrite. The large density of dislocations in the ferrite present in bainite, and the fine size of the bainite platelets, make this ferrite harder than it normally would be. Bainitic steels are generally stronger and harder than pearlitic steels, yet they exhibit a desirable combination of strength and ductility. The hardness of bainite can be between that of pearlite and untempered martensite in the same steel hardness.

Bainite was first described by E. S. Davenport and Edgar Bain. Therefore the name bainite. In the late 1920s, they initiated the study of quenched steels by a method called isothermal transformation.

Austempering

Austempering is a heat treatment used to form pure bainite, a transitional microstructure found between pearlite and martensite. Austempering consists of rapidly cooling the metal part from the austenitizing temperature to about 230 to 400°C, holding in a constant temperature to allow isothermal transformation. To avoid the formation of pearlite or martensite, the steel is quenched in a bath of molten metals or salts. The steel is then held at the bainite-forming temperature, beyond the point where the temperature reaches an equilibrium until the bainite fully forms. The steel is then removed from the bath and allowed to air-cool without forming either pearlite or martensite. Austempering can produce upper or lower bainite depending on the holding temperature.

Bainite is a plate-like microstructure that forms in steels from austenite when cooling rates are not rapid enough to produce martensite but are still fast enough so that carbon does not have enough time to diffuse to form pearlite. The key difference between pearlite and bainite is that pearlite contains alternating layers of ferrite and cementite, whereas bainite has a plate-like microstructure.

A fine non-lamellar structure, bainite commonly consists of cementite and dislocation-rich ferrite. The large density of dislocations in the ferrite present in bainite, and the fine size of the bainite platelets, make this ferrite harder than it normally would be. Bainitic steels are generally stronger and harder than pearlitic steels, yet they exhibit a superior impact resistance. The hardness of bainite can be between that of pearlite and untempered martensite in the same steel hardness.

Austempering is applicable to most medium-carbon steels and alloy steels. Low-alloy steels are usually restricted to 9.5 mm or thinner sections, while more hardenable steels can be austempered in sections up to 50 mm thick.

Other Common Phases in Steels and Irons

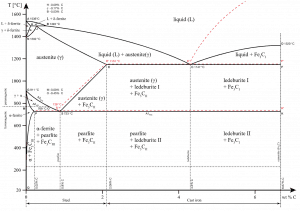

Heat treatment of steels requires an understanding of both the equilibrium phases and the metastable phases that occur during heating and/or cooling. For steels, the stable equilibrium phases include:

- Ferrite. Ferrite or α-ferrite is a body-centered cubic structure phase of iron that exists below temperatures of 912°C for low concentrations of carbon in iron. α-ferrite can only dissolve up to 0.02 percent of carbon at 727°C. This is because of the configuration of the iron lattice, which forms a BCC crystal structure. The primary phase of low-carbon or mild steel and most cast irons at room temperature is ferromagnetic α-Fe.

- Austenite. Austenite, also known as gamma-phase iron (γ-Fe), is a non-magnetic face-centered cubic structure phase of iron. Austenite in iron-carbon alloys is generally only present above the critical eutectoid temperature (723°C) and below 1500°C, depending on carbon content. However, it can be retained to room temperature by alloy additions such as nickel or manganese. Carbon plays an important role in heat treatment because it expands the temperature range of austenite stability. Higher carbon content lowers the temperature needed to austenitize steel—such that iron atoms rearrange themselves to form an fcc lattice structure. Austenite is present in the most commonly used type of stainless steel, which is very well known for its corrosion resistance.

- Graphite. Adding a small amount of non-metallic carbon to iron trades its great ductility for greater strength.

- Cementite. Cementite (Fe3C) is a metastable compound, and under some circumstances, it can be made to dissociate or decompose to form α-ferrite and graphite, according to the reaction: Fe3C → 3Fe (α) + C (graphite). Cementite, in its pure form, is ceramic and is hard and brittle, making it suitable for strengthening steel. Its mechanical properties are a function of its microstructure, which depends upon how it is mixed with ferrite.

The metastable phases are:

Pearlite. In metallurgy, pearlite is a layered metallic structure of two phases, composed of alternating layers of ferrite (87.5 wt%) and cementite (12.5 wt%) that occurs in some steels and cast irons. It is named for its resemblance to the mother of the pearl.

Pearlite. In metallurgy, pearlite is a layered metallic structure of two phases, composed of alternating layers of ferrite (87.5 wt%) and cementite (12.5 wt%) that occurs in some steels and cast irons. It is named for its resemblance to the mother of the pearl.- Martensite. Martensite is a very hard metastable structure with a body-centered tetragonal (BCT) crystal structure. Martensite is formed in steels when austenite’s cooling rate is so high that carbon atoms do not have time to diffuse out of the crystal structure in large enough quantities to form cementite (Fe3C).

- Bainite. Bainite is a plate-like microstructure that forms in steels from austenite when cooling rates are not rapid

enough to produce martensite but are still fast enough so that carbon does not have enough time to diffuse to form pearlite. Bainitic steels are generally stronger and harder than pearlitic steels, yet they exhibit a desirable combination of strength and ductility.