Superalloys, or high-performance alloys, are non-ferrous alloys that exhibit outstanding strength and surface stability at high temperatures. Their key characteristic is their ability to operate safely at a high fraction of their melting point (up to 85% of their melting points (Tm) expressed in degrees Kelvin, 0.85). Superalloys are generally used at temperatures above 540 °C (1000 °F); ordinary steel and titanium alloys lose their strength at these temperatures. Also, corrosion is common in steels at this temperature. At high temperatures, superalloys retain mechanical strength, thermal creep deformation, surface stability, and resistance to corrosion or oxidation. Some nickel-based superalloys can withstand temperatures beyond 1200°C, depending on the composition of the alloy. Superalloys are often cast as a single crystal. While grain boundaries may provide strength, they decrease creep resistance.

Superalloys, or high-performance alloys, are non-ferrous alloys that exhibit outstanding strength and surface stability at high temperatures. Their key characteristic is their ability to operate safely at a high fraction of their melting point (up to 85% of their melting points (Tm) expressed in degrees Kelvin, 0.85). Superalloys are generally used at temperatures above 540 °C (1000 °F); ordinary steel and titanium alloys lose their strength at these temperatures. Also, corrosion is common in steels at this temperature. At high temperatures, superalloys retain mechanical strength, thermal creep deformation, surface stability, and resistance to corrosion or oxidation. Some nickel-based superalloys can withstand temperatures beyond 1200°C, depending on the composition of the alloy. Superalloys are often cast as a single crystal. While grain boundaries may provide strength, they decrease creep resistance.

They were initially developed for use in aircraft piston engine turbosuperchargers. Today, the most common application is in aircraft turbine components, which must withstand exposure to severely oxidizing environments and high temperatures for reasonable periods. Current applications include:

- Aircraft gas turbines

- Steam turbine power plants

- Medical applications

- Space vehicles and rocket engines

- Heat-treating equipment

- Nuclear power plants

Nickel is the base element for superalloys, a group of nickel, iron-nickel, and cobalt alloys used in jet engines. These metals have excellent resistance to thermal creep deformation and retain their stiffness, strength, toughness, and dimensional stability at temperatures much higher than the other aerospace structural materials.

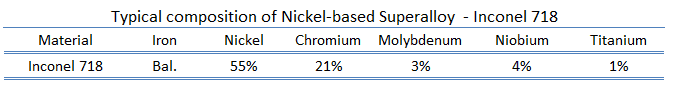

Nickel-based Superalloys

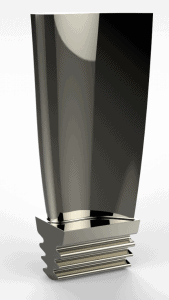

Nickel-based superalloys currently constitute over 50% of the weight of advanced aircraft engines. Nickel-base superalloys include solid-solution-strengthened alloys and age-hardenable alloys. Age-hardenable alloys are austenitic (fcc) matrix dispersed with coherent precipitation of a Ni3(Al, Ti) intermetallic with an fcc structure. Ni-based superalloys are alloys with nickel as the primary alloying element and are preferred as blade material in the previously discussed applications, rather than Co- or Fe-based superalloys. Ni-based superalloys are significant for their high strength, creep, and corrosion resistance at high temperatures. It is common to cast turbine blades in directionally solidified or single-crystal forms. Single-crystal blades are mainly used in the first row in the turbine stage.