Soldering is a technique for joining metals using a filler metal alloy with a melting temperature of less than 425°C (800°F). Because of this lower temperature and different alloys used as fillers, the metallurgical reaction between filler and workpiece is minimal, resulting in a weaker joint. In electronics assembly, the eutectic alloy with 63% tin and 37% lead (or 60/40, which is almost identical in melting point) has been the alloy of choice. This eutectic alloy has a melting point lower than tin or lead. The solder is distributed between closely fitted joint surfaces by capillary action. Heat is required to raise the joint to a suitable temperature to melt the solder and promote the action of the soldering flux that has been prepositioned on the surface of the metal. Soldering is performed in many industries, from exotic applications in electronics and aerospace to everyday plumbing applications. The major soldering alloys are combinations of tin and lead or the same alloys.

Soldering is a technique for joining metals using a filler metal alloy with a melting temperature of less than 425°C (800°F). Because of this lower temperature and different alloys used as fillers, the metallurgical reaction between filler and workpiece is minimal, resulting in a weaker joint. In electronics assembly, the eutectic alloy with 63% tin and 37% lead (or 60/40, which is almost identical in melting point) has been the alloy of choice. This eutectic alloy has a melting point lower than tin or lead. The solder is distributed between closely fitted joint surfaces by capillary action. Heat is required to raise the joint to a suitable temperature to melt the solder and promote the action of the soldering flux that has been prepositioned on the surface of the metal. Soldering is performed in many industries, from exotic applications in electronics and aerospace to everyday plumbing applications. The major soldering alloys are combinations of tin and lead or the same alloys.

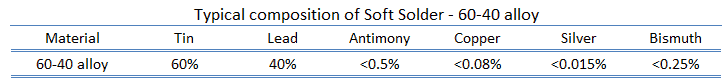

Tin is an important constituent in solders because it wets and adheres to many common base metals at temperatures considerably below their melting points. Small amounts of various metals, notably antimony and silver, are added to tin-lead solders to increase their strength. 60-40 solder provides strong and reliable joints under various environmental conditions. High-tin solders are also used for joining parts of electrical apparatuses because their electrical conductivity is higher than that of high-lead solders. These soldiers are also used where lead may be a hazard, for example, in contact with drinking water or food.