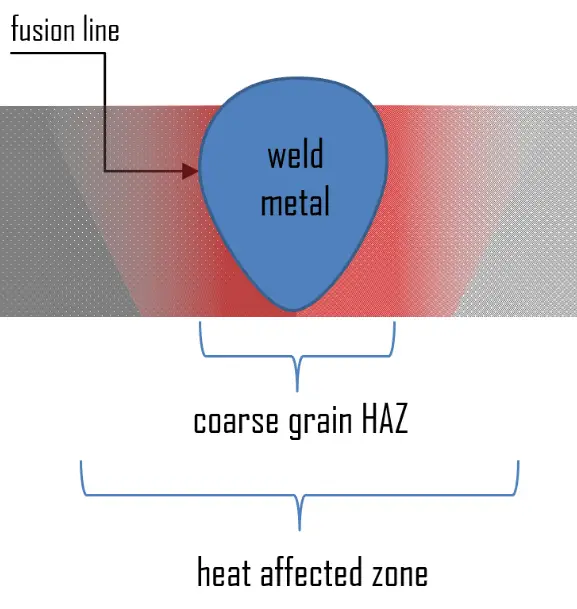

This section will focus on fusion welding, which is more common than solid-state welding. Fusion welding is used to manufacture many everyday items, including airplanes, cars, and structures. Using a heat source with sufficient power makes it possible to fuse through a complete section of a very thick plate. The weld pool produced is difficult to control, and the heat-affected zone (HAZ) of such welds has a relatively coarse grain, adversely affecting the mechanical properties of the steel. The heat-affected zone (HAZ) is a ring surrounding the weld in which the temperature of the welding process, combined with the stresses of uneven heating and cooling, alters the heat-treatment properties of the alloy. The effects of welding on the material surrounding the weld can be detrimental—depending on the materials used and the heat input of the welding process used. The HAZ can be of varying size and strength. In the weld pool, heat is transported by means of convection and conduction.

This section will focus on fusion welding, which is more common than solid-state welding. Fusion welding is used to manufacture many everyday items, including airplanes, cars, and structures. Using a heat source with sufficient power makes it possible to fuse through a complete section of a very thick plate. The weld pool produced is difficult to control, and the heat-affected zone (HAZ) of such welds has a relatively coarse grain, adversely affecting the mechanical properties of the steel. The heat-affected zone (HAZ) is a ring surrounding the weld in which the temperature of the welding process, combined with the stresses of uneven heating and cooling, alters the heat-treatment properties of the alloy. The effects of welding on the material surrounding the weld can be detrimental—depending on the materials used and the heat input of the welding process used. The HAZ can be of varying size and strength. In the weld pool, heat is transported by means of convection and conduction.

An understanding of heat transfer is important in producing welds since the properties of a weldment are controlled by its geometry and by the composition and structure of the materials being welded.