Resistance welding (ERW) is a process that involves generating heat from the flow of electrical current through the joined parts. Small pools of molten metal are formed at the weld area as a high current (1000–100,000 A) is passed through the metal. Electric resistance welding is widely used, for example, in manufacturing steel pipes and assembling bodies for automobiles. The vehicle manufacturing industry, among others, employs the resistance processes extensively in applications in which the product design specifies gauge thicknesses that are lapped. Fully automatic and robotic systems are used for many of these applications.

Resistance welding (ERW) is a process that involves generating heat from the flow of electrical current through the joined parts. Small pools of molten metal are formed at the weld area as a high current (1000–100,000 A) is passed through the metal. Electric resistance welding is widely used, for example, in manufacturing steel pipes and assembling bodies for automobiles. The vehicle manufacturing industry, among others, employs the resistance processes extensively in applications in which the product design specifies gauge thicknesses that are lapped. Fully automatic and robotic systems are used for many of these applications.

Commonly implemented resistance welding processes are:

- resistance spot welding (RSW),

- resistance seam welding (RSEW),

- resistance projection welding (RPW)

- resistance stud welding.

The main process variables associated with these resistance welding processes are welding current, welding time, electrode force or pressure, electrode material, and tip configuration. Resistance welding (RW) was invented in 1886 by Professor Elihu Thomson, and it is one of the simplest and most commonplace fusion welding processes.

Resistance Spot Welding – RSW

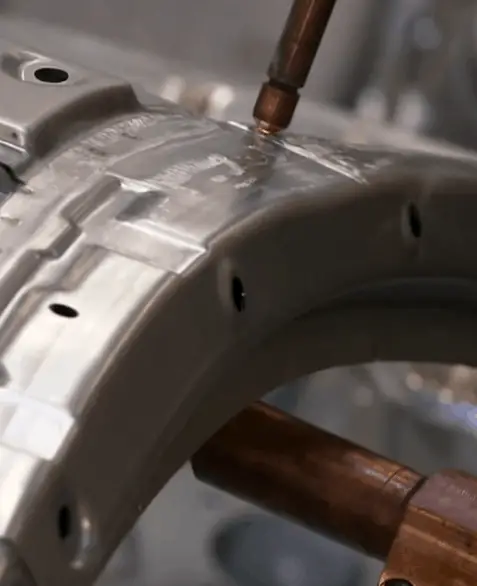

Resistance spot welding or spot welding is a welding process used to join two or more overlapping metal sheets, studs, projections, or other closely fitted surfaces in one or more spots. In this method, the joint is produced by the heat generated due to the resistance of workpieces to the flow of current and the application of pressure. The weld is limited to the spots on overlapped workpieces. Hence not continuous. The pointed copper electrodes conduct the welding current to the work spot and also serve to apply pressure to form the strong joint. These contacting surfaces are heated by a short-timed pulse of low-voltage, high-amperage current to form a fused nugget of weld metal. Small pools of molten metal are formed at the weld area as a high current (1000–100,000 A) is passed through the metal. When the flow of current is stopped, the electrode pressure is maintained while the weld metal cools rapidly and solidifies. The electrodes are made of either precipitated strengthened copper-chromium and/or zirconium alloy and have to be exchanged after a certain amount of welds.

The advantages of the method include efficient energy use, limited workpiece deformation, high production rates, easy automation, and no required filler materials. The principal disadvantage is the need to have accessibility to both sides of the workpiece as opposed to being able to make welds from one side only. The most commonly used welding methods for automotive applications include resistance spot welding (RSW). The vehicle manufacturing industry, among others, employs the resistance processes extensively in applications in which the product design specifies gauge thicknesses that are lapped. Fully automatic and robotic systems are used for many of these applications. On average, the conventional steel body of a car contains 4500 spot weld joints.

Resistance Seam Welding – RSEW

Resistance seam welding is a process similar to that of the spot welding process. Still, instead of pointed electrodes, wheel-shaped electrodes roll along and often feed the workpiece, making it possible to make long continuous welds. This produces a weld at the faying surfaces of two similar metals. The electrodes are often disc-shaped and rotate as the material passes between them. The seam may be a butt joint or an overlap joint and is usually an automated process. The joint is normally gastight or liquid-tight. A series of welds is made without retracting the electrode wheels or releasing the electrode force between spots, but the wheels may advance either intermittently or continuously.

Like spot welding, seam welding relies on two electrodes, usually made from copper, to apply pressure and current. Seam welding produces an extremely durable weld because the joint is forged due to the heat and pressure applied. A common use of seam welding is during the manufacture of round or rectangular steel tubing.