Arc welding processes use a welding power supply to create and maintain an electric arc between an electrode and the base material to melt metals at the welding point. The intense heat produced by the arc quickly melts a portion of the base metal, resulting in the formation of a weld. This electrical arc is around 3590°C in its center. Filler metal is added in most welding processes to increase the volume and strength of the weld joint. A pool of molten metal, consisting of base and filler metal is formed near the tip of the electrode. As the electrode is moved along the joint, the molten metal solidifies in its wake.

The welding power supply can use either direct current (DC), alternating current (AC), and consumable or non-consumable electrodes. The welding region is sometimes protected by some type of inert or semi-inert gas, known as a shielding gas. In arc welding, the length of the arc is directly related to the voltage, and the amount of heat input is related to the current. The voltage supplied by power companies for industrial purposes-120 volts (V), 230 V, 380 V, or 480 V is too high for use in arc welding. Therefore, the first function of an arc welding power source is to reduce the high input or line voltage to a suitable output voltage range, 20 V to 80 V. Constant current power supplies are most often used for manual welding processes such as gas tungsten arc welding and shielded metal arc welding because they maintain a relatively constant current even as the voltage varies. This is important because, in manual welding, it can be difficult to hold the electrode perfectly steady, and as a result, the arc length and thus voltage tend to fluctuate.

Shielded Metal Arc Welding – SMAW

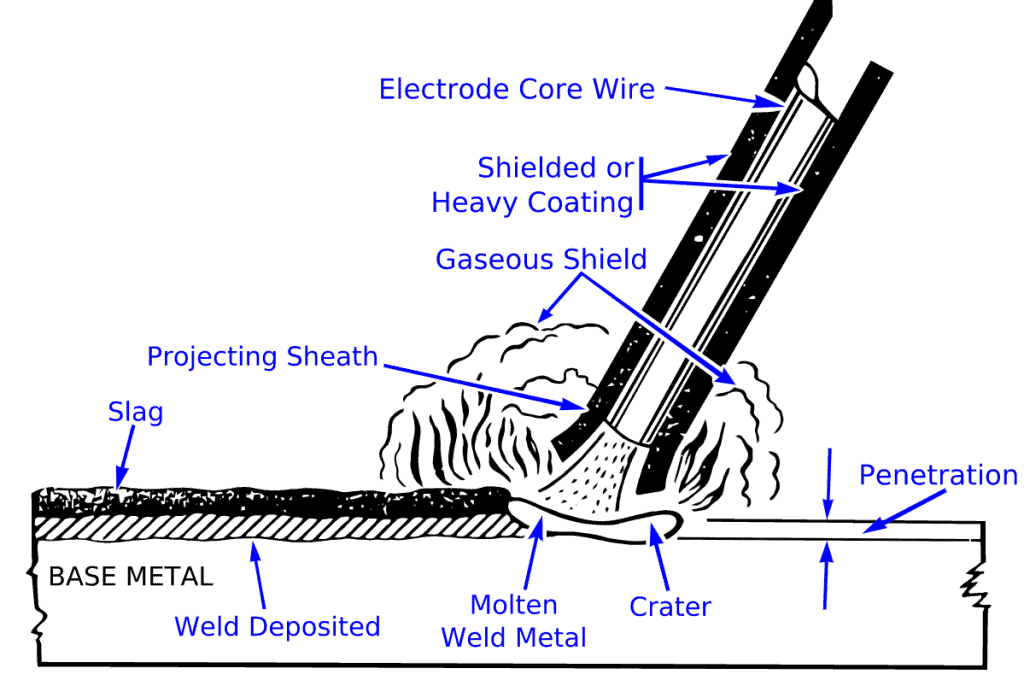

Shielded metal arc welding (SMAW) is one of the most common types of arc welding. It is also known as manual metal arc welding (MMAW) or stick welding. Shielded metal arc welding (SMAW) uses an electrode consisting of a filler metal rod coated with flux that protects the weld area from oxidation and contamination by producing carbon dioxide (CO2) gas during the welding process. The filler metal used in the rods must be compatible with the metal to be welded. The composition is usually close to that of the base metal. Electric current is used to strike an arc between the base material and the consumable electrode rod.

The SMAW process is the simplest in terms of equipment requirements. It is versatile and can be performed with relatively inexpensive equipment, making it well suited to shop jobs and field work. An operator can become proficient with a modest amount of training and achieve mastery with experience. Most new welders start as “stick welders” and develop the necessary skills through training and experience. Weld times are rather slow since the consumable electrodes must be frequently replaced and because slag, the residue from the flux, must be chipped away after welding.