Strengthening of Metals

The strength of metals and alloys can be modified through various combinations of cold working, alloying, and heat treating. As discussed in the previous section, the ability of a crystalline material to deform largely plastically depends on the ability for dislocation to move within a material. Therefore, impeding the movement of dislocations will result in the strengthening of the material. For example, a microstructure with finer grains typically results in higher strength and superior toughness than the same alloy with physically larger grains. In the case of grain size, there may also be a tradeoff between strength and creep characteristics. Other strengthening mechanisms are achieved at the expense of lower ductility and toughness. There are many strengthening mechanisms, which include:

- Solid Solution Strengthening (alloying)

- Work Hardening (Cold Working)

- Precipitation Hardening

- Grain Refinement

- Transformation Hardening

Grain Refinement – Grain Boundary Strengthening

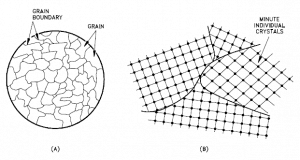

Grain-boundary strengthening (or Hall–Petch strengthening) strengthens materials by changing their average crystallite (grain) size. The size of the grain determines the properties of the metal. For example, smaller grain size increases tensile strength and tends to increase ductility. Larger grain size is preferred for improved high-temperature creep properties. Decreasing the grain size also is an effective way to increase ductility. When grain size is reduced, there are more grains with a greater number of arbitrarily aligned slip planes for the dislocations in the grains. This provides more opportunity for some slips to occur in a stressed material. Grain boundaries act as an impediment to dislocation motion for the following two reasons:

- Dislocation must change its direction of motion due to the different orientations of grains.

- Discontinuity of slip planes from grain one to grain two.

Thus, grain refinement provides an important means to improve strength, ductility, and toughness. Many other strengthening mechanisms are achieved at the expense of ductility and toughness. For many materials, the yield strength σ varies with grain size according to

σy = σy,0 + k/dx

In this expression, termed the Hall–Petch equation, k is a constant, d is the average grain diameter, and σy,0 is the original yield stress. Note that this equation is not valid for both very large (i.e., coarse) grain and extremely fine-grain polycrystalline materials.

The synergistic effect of alloying elements and heat treatment produces a tremendous variety of microstructures and properties of steels.

- Vanadium. Vanadium is generally added to steel to inhibit grain growth during heat treatment. Controlling grain growth improves the strength and toughness of hardened and tempered steels. The size of the grain determines the properties of the metal. For example, smaller grain size increases tensile strength and tends to increase ductility. Larger grain size is preferred for improved high-temperature creep properties.

- Tungsten. Tungsten produces stable carbides and refines grain size to increase hardness, particularly at high temperatures. Tungsten is used extensively in high-speed tool steels and has been proposed as a substitute for molybdenum in reduced-activation ferritic steels for nuclear applications.