The key feature of LWRs fuel cycles is that there are many fuel assemblies in the core. These assemblies have different multiplying properties because they may have different enrichment and different burnup. Generally, a common fuel assembly contains energy for approximately 4 years of operation at full power. Once loaded, the fuel stays in the core for 4 years, depending on the design of the operating cycle. During these 4 years, the reactor core has to be refueled. During refueling, every 12 to 18 months, some of the fuel – usually one-third or one-quarter of the core – is removed to the spent fuel pool. At the same time, the remainder is rearranged to a location in the core better suited to its remaining level of enrichment. The removed fuel (one-third or one-quarter of the core, i.e., 40 assemblies) must be replaced by fresh fuel assemblies.

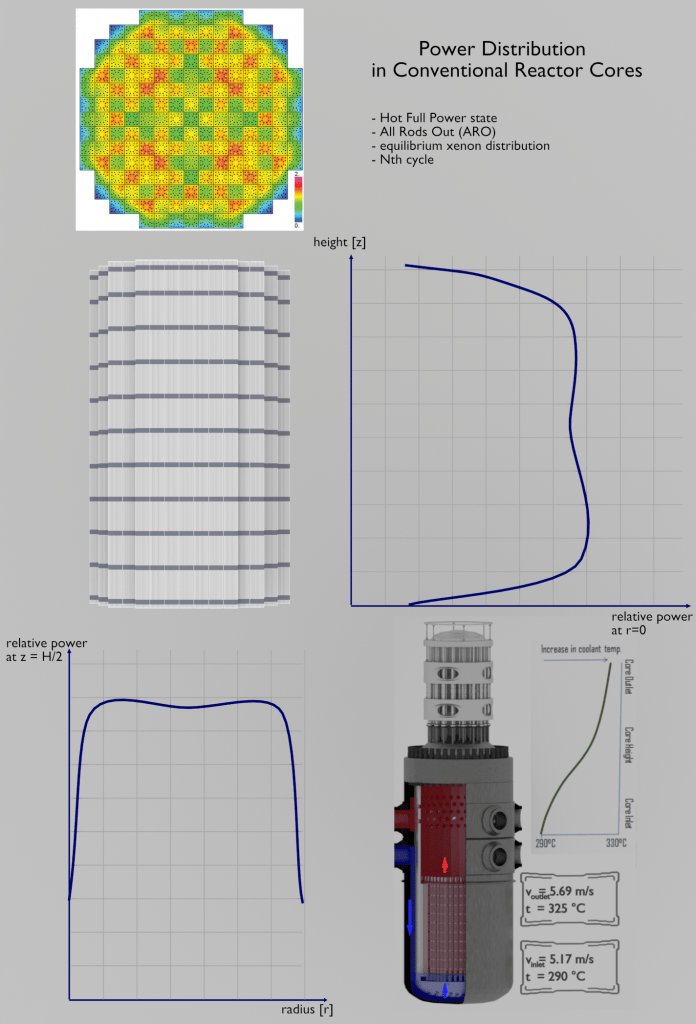

Many different loading patterns have been considered, with the general conclusion that more energy is extracted from the fuel when the power distribution in the core is as flat as possible. In principle, these loading strategies may be divided into two categories:

- Out-In Loading Patterns. In the out-in loading pattern, the fresh fuel batch is placed at the periphery of the core, while the intermediate and high burnup batches are placed at the center of the core. The highest burnup batch is discharged at refueling, the other batches are shifted inward, and a fresh batch is loaded at the periphery. The out-in loading pattern has been found to go too far because the power distribution is depressed in the center and peaked at the periphery. An additional difficulty is producing a large number of fast neutrons at the periphery that leak from the core and damage the pressure vessel.

- In-Out Loading Patterns. To enhance the neutron and fuel economy, core designers design the low leakage loading patterns, in which fresh fuel assemblies are not situated in the peripheral positions of the reactor core. The peripheral positions are loaded with the fuel with the highest fuel burnup. These “high” burnup assemblies have inherently lower relative power (due to the lower kinf and because they feel the presence of non-multiplying environment – reflector) compared to the average assemblies. During fuel depletion, the flux distribution at the periphery of the core increases, especially in low leakage loading patterns. This process is caused by reducing the differences in kinf between fresh fuel assemblies and peripheral high-burnup assemblies. Since the peripheral assemblies have low relative power, these loading patterns reach slightly higher peaking factors than Out-In loading patterns. On the other hand, enhanced neutron and fuel economy allow less fresh fuel or less enriched fuel during refueling. A secondary benefit is that loading the “high” burnup assemblies in the periphery reduces the neutron flux on the pressure vessel. This provides additional protection of the reactor vessel from irradiation embrittlement, caused especially by fast neutrons.