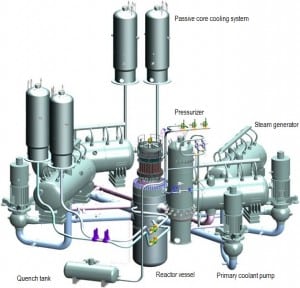

In typical modern pressurized water reactors (PWRs), the Reactor Coolant System (RCS), shown in the figure, consists of:

- the reactor vessel contains the nuclear fuel

- four parallel heat transfer loops connected to a reactor vessel.

- each loop contains a main coolant pump and a steam generator.

- the system includes a pressurizer and its auxiliary systems

All RCS components are located inside the containment building.

Source: gidropress.podolsk.ru

used with permission of АО ОКБ “ГИДРОПРЕСС”

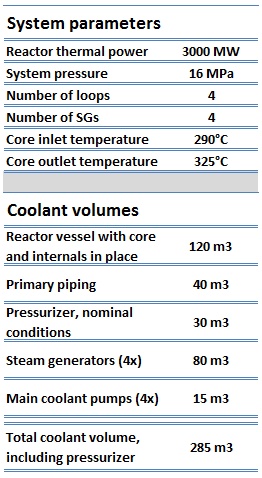

There is compressed liquid water inside the reactor vessel, loops, and steam generators at normal operation. The pressure is maintained at approximately 16MPa. At this pressure, water boils at approximately 350°C (662°F). The inlet temperature of the water is about 290°C (554°F). The water (coolant) is heated in the reactor core to approximately 325°C (617°F) as the water flows through the core. As it can be seen, the reactor contains approximately 25°C subcooled coolant (distance from the saturation). This high pressure is maintained by the pressurizer, a separate vessel that is connected to the primary circuit (hot leg) and partially filled with water (partially with saturated steam) which is heated to the saturation temperature (boiling point) for the desired pressure by submerged electrical heaters. The temperature in the pressurizer can be maintained at 350 °C. About 60% of the pressurizer volume occupies the compressed water at normal conditions, and about 40% of the volume occupies the saturated steam.

This high pressure is maintained by the pressurizer, a separate vessel that is connected to the primary circuit (hot leg) and partially filled with water (partially with saturated steam) which is heated to the saturation temperature (boiling point) for the desired pressure by submerged electrical heaters. The temperature in the pressurizer can be maintained at 350 °C. About 60% of the pressurizer volume occupies the compressed water at normal conditions, and about 40% of the volume occupies the saturated steam.

Volumes of typical PWR are in the following table.

It is an illustrative example, and the following data do not correspond to any reactor design.

It must be noted the volume of the coolant significantly changes with the temperature of the coolant. The total mass of the coolant always remains the same. A change in water volume is not a change in water inventory. The reactor coolant volume changes with temperature because of changes in density. Most substances expand when heated and contract when cooled. However, the amount of expansion or contraction varies, depending on the material. This phenomenon is known as thermal expansion. The change in volume of a material that undergoes a temperature change is given by the following relation:

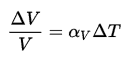

where ∆T is the temperature change, V is the original volume, ∆V is the volume change, and αV is the coefficient of volume expansion.

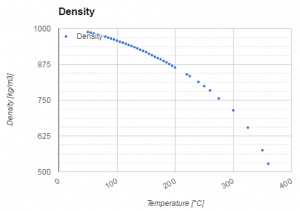

The volumetric thermal expansion coefficient for water is not constant over the temperature range and increases with the temperature (especially at 300°C). Therefore the change in density is not linear with temperature (as indicated in the figure).

See also: Steam Tables.

At normal conditions, the total volume of coolant in the reactor coolant system is almost constant. On the other hand, during transient load conditions, the volume can significantly change. These changes are naturally reflected in a change in pressurizer water level. When the average temperature of reactor coolant goes down gradually, the total water volume also decreases, which lowers the pressurizer level. On a gradual load pick-up, the increase in the average temperature of reactor coolant causes the total water volume to expand, raising the pressurizer level. These effects must be controlled by a pressurizer level control system.