Pressure stresses are stresses induced in vessels containing pressurized materials. The loading is provided by the same force producing the pressure. Thermal stresses exist whenever temperature gradients are present in a material, and different temperatures produce different expansions and subject materials to internal stress. This type of stress is particularly noticeable in mechanisms operating at high temperatures cooled by a cold fluid. These stresses can be comprised of tensile stress, which is stress arising from forces acting in opposite directions tending to pull a material apart, and compressive stress, which is stress arising from forces acting in opposite directions tending to push a material together. These stresses, cyclic in nature, can lead to fatigue failure of the materials.

By contrast, the reactor pressure vessel and piping are subjected to large load variations, but the cycle frequency is low; therefore, high ductility is the main requirement for the steel. Thermal sleeves, such as spray nozzles and surge lines, are used in some cases to minimize thermal stresses. Heat up, and cooldown rate limits are based upon the impact on the future fatigue life of the plant. The heat up and cooldown limits ensure that the plant’s fatigue life is equal to or greater than the plant’s operational life. Additionally, plant design modifications include heating up of the Emergency Core Cooling System (ECCS) water tanks or sumps to reduce the temperature difference between injected water and the material of RPV.

One safety issue that is a long-term problem brought on by the aging of nuclear facilities is pressurized thermal shock (PTS). PTS is the shock experienced by a thick-walled vessel due to the combined stresses from a rapid temperature and/or pressure change.

Special Reference: Reactor Pressure Vessel Status Report, U.S. NRC. NUREG-1511. Office of Nuclear Reactor Regulation U.S. Nuclear Regulatory Commission, Washington, 1994.

Pressure and Temperature (P/T) Limits

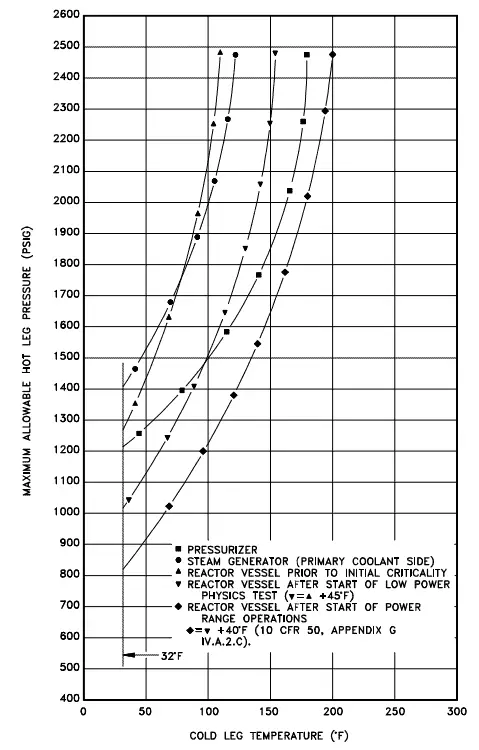

Pressure and Temperature (P/T) Limits are limiting curves defined in the plant’s Technical Specification. Each P/T limit curve defines an acceptable region for normal operation. 10 CFR 50, Appendix G, requires the establishment of P/T limits for specific material fracture toughness requirements of the pressure boundary materials. The P-T limits are derived based on linear elastic fracture mechanics (LEFM) analyses. In these analyses, the minimum temperature necessary to ensure adequate margins against RPV failure is determined as a function of pressure.

P/T is based on the limitations of the reactor vessel and head stress and the need to preclude reactor vessel and head brittle fracture. The usual use of the curves is operational guidance during heat up or cooldown maneuvering when pressure and temperature indications are monitored and compared to the applicable curve to determine that operation is within the allowable region. The curves used by operations also incorporate instrument error to ensure adequate safety margin. Because of the embrittling effects of neutron irradiation, the MPT curve will shift to the right over core life to account for the increased brittleness or decreased ductility.