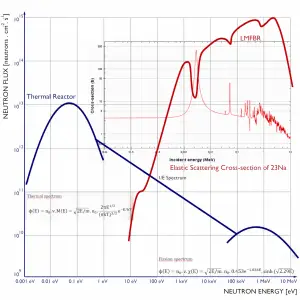

From the physics point of view, the main differences among reactor types arise from differences in their neutron energy spectra. The basic classification of nuclear reactors is based upon the average energy of the neutrons, which cause the bulk of the fissions in the reactor core. From this point of view, nuclear reactors are divided into two categories:

- Thermal Reactors. Almost all of the current reactors built to date use thermal neutrons to sustain the chain reaction. These reactors contain neutron moderator that slows neutrons from fission until their kinetic energy is more or less in thermal equilibrium with the atoms (E < 1 eV) in the system.

- Fast Neutron Reactors. Fast reactors contain no neutron moderator and use less-moderating primary coolants because they use fast neutrons (E > 1 keV) to cause fission in their fuel.

Comparison of neutron spectra in a typical LWR and a sodium-cooled fast breeder reactor. Note that, the fast reactor spectrum is highly affected by the elastic scattering cross-section of used coolant.

Comparison of neutron spectra in a typical LWR and a sodium-cooled fast breeder reactor. Note that, the fast reactor spectrum is highly affected by the elastic scattering cross-section of used coolant.Types of Nuclear Reactors

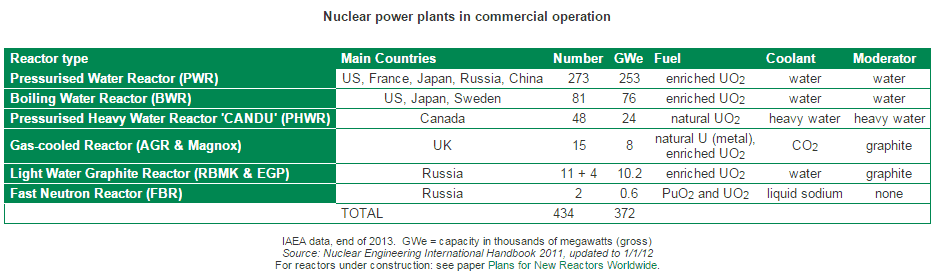

This article is about the main conventional types of nuclear reactors.

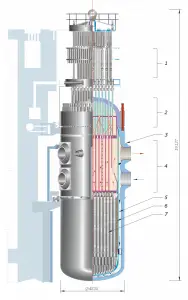

Pressurized Water Reactor – PWR

Source: www.wikipedia.org

Pressurized water reactors use a reactor pressure vessel (RPV) to contain the nuclear fuel, moderator, control rods, and coolant. They are cooled and moderated by high-pressure liquid water (e.g.,, 16MPa). At this pressure, water boils at approximately 350°C (662°F). The inlet temperature of the water is about 290°C (554°F). The water (coolant) is heated in the reactor core to approximately 325°C (617°F) as the water flows through the core. As it can be seen, the reactor has approximately 25°C subcooled coolant (distance from the saturation).

The hot water that leaves the pressure vessel through the hot leg nozzle is looped through a steam generator, which heats a secondary water loop to steam that can run turbines and generators. Secondary water in the steam generator boils at a pressure of approximately 6-7 MPa, which equals 260°C (500°F) saturated steam. Typical reactor nominal thermal power is about 3400MW, thus corresponds to the net electric output of 1100MW. Therefore the typical efficiency of the Rankine cycle is about 33%.

See also: Pressurized Water Reactor.

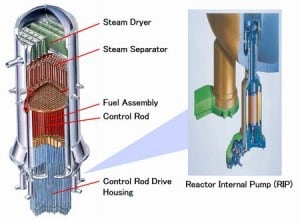

Boiling water reactor – BWR

Source: www.nuclearstreet.com

A boiling water reactor is cooled and moderated by water like a PWR, but at a lower pressure (7MPa), which allows the water to boil inside the pressure vessel producing the steam that runs the turbines. A BWR is like a PWR but with many differences. The BWRs don’t have any steam generator. Unlike a PWR, there is no primary and secondary loop. The thermal efficiency of these reactors can be higher, and they can be simpler and even potentially more stable and safe. But the disadvantage of this concept is that any fuel leak can make the water radioactive and that radioactivity can reach the turbine and the rest of the loop.

See also: Boiling Water Reactor

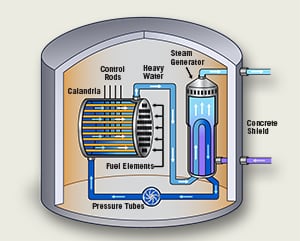

CANDU – Heavy Water Reactor

The CANDU reactor design (or PHWR – Pressurized Heavy Water Reactor) has been developed since the 1950s in Canada, and more recently, also in India. These reactors are heavy water-cooled and moderated pressurized water reactors. Instead of using a single large reactor vessel like a PWR or BWR, the nuclear core is contained in hundreds of pressure tubes. PHWRs generally use natural uranium (0.7% U-235) oxide as fuel. Hence they need a more efficient moderator, in this case, heavy water (D2O).

Source: www.cameco.com

The reactor core is in a large tank called calandria. There is heavy water as the moderator in this tank. The calandria is penetrated by several hundred horizontal pressure tubes. These tubes form channels for the fuel. The fuel is cooled by heavy water flow under high pressure in the primary cooling circuit, reaching 290°C. The moderator in the tank and the coolant in the channels are separated. The hot coolant that leaves the channels goes to a steam generator, which in turn heats a secondary loop of water to steam that can run turbines and generator (as in the PWR).

See also: CANDU – Heavy Water Reactor

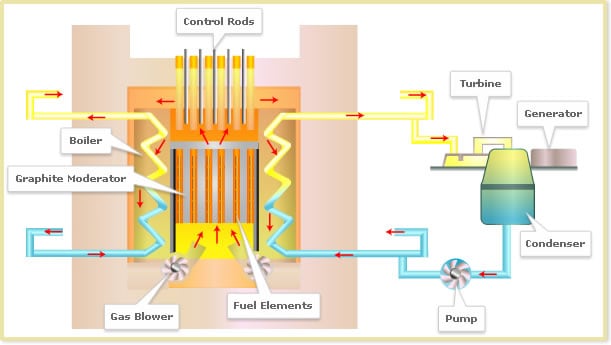

Advanced Gas-cooled Reactor

An advanced gas-cooled reactor (AGR) is a British design of a nuclear reactor. AGRs are using graphite as the neutron moderator and carbon dioxide as coolant. AGRs were developed from the Magnox-type reactor. These are the second generation of British gas-cooled reactors. AGRs are operating at a higher gas temperature for improved thermal efficiency, thus requires stainless steel fuel cladding to withstand the higher temperature. Low-enriched uranium fuel is needed because the stainless steel fuel cladding has a higher neutron capture cross-section than Magnox fuel (magnesium non-oxidizing alloy).

The fuel is uranium oxide pellets, enriched to 2.5-3.5%, in stainless steel tubes. The carbon dioxide circulates through the core, reaching 650°C (for improved thermal efficiency) and then past steam generator tubes outside it, but still inside the concrete and steel pressure vessel (hence ‘integral’ design). Control rods penetrate the moderator, and a secondary shutdown system involves injecting nitrogen into the coolant.

See also: Advanced Gas-cooled Reactor

Source: www.hknuclear.com

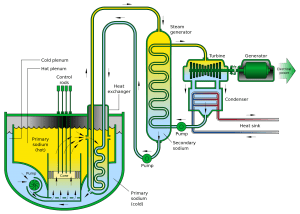

Fast Neutron Reactor

A fast neutron reactor is a nuclear reactor in which fast neutrons sustain the fission chain reaction. That means the neutron moderator (slowing down) in such reactors is undesirable. This is a key advantage of fast reactors because fast reactors have a significant excess of neutrons (due to low parasitic absorption), unlike PWRs (or LWRs).

Source: wikipedia.org

On the other hand, such reactors must compensate for the missing reactivity from the neutron moderator effect. They use fuel with higher enrichment when compared to that required for a thermal reactor. Fast reactors require enrichments of about 10% or more. Most fast reactors use hexagonal lattice cells (as VVER reactors) to reach smaller volume ratios of coolant to fuel. Generally, fast reactors have to utilize much more compact nuclear cores than thermal reactors (PWRs or BWRs) to reach the required core reactivity. This implies the fast reactor cores achieve higher power densities. Consequently, they cannot use water as a coolant because of its moderating properties and insufficient thermal properties. The solution given this problem is to use another coolant as liquid sodium or lead.

See also: Fast Neutron Reactor

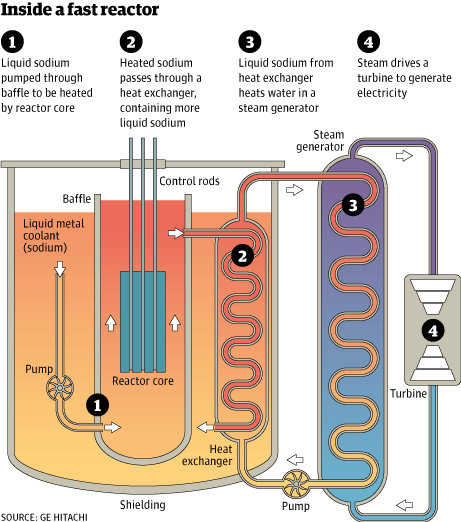

Breeder Reactor

Source GE HITACHI

A breeder reactor is essentially a particular configuration of a fast reactor. Fast reactors generally have an excess of neutrons (due to low parasitic absorption). The neutrons given off by fission reactions can “breed” more fuel from otherwise non-fissionable isotopes or be used for another purpose (e.g.,transmutation of spent nuclear fuel). The most common breeding reaction is an absorption reaction on uranium-238, where a plutonium-239 from non-fissionable uranium-238 is produced. A key parameter of breeder reactors is a breeding ratio, although this ratio also describes the thermal reactor’s fuel cycle.

The term “breeder” refers to the types of configurations which can be the breeding ratio higher than 1. That means such reactors produce more fissionable fuel than they consume (i.e., more fissionable Pu-239 is produced from non-fissionable uranium-238 than consumed initial U-235+Pu-239 fuel).

Production of fissile material in a reactor occurs by neutron irradiation of fertile material, particularly uranium-238 and thorium-232. These materials are bred, either in the fuel or in a breeder blanket surrounding the core.

See also: Breeder Reactor