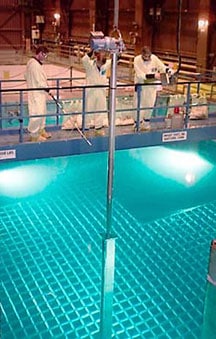

A spent fuel pool (SFP) is a storage pool for spent nuclear fuel from nuclear reactors. A spent fuel pool may be located inside the containment building or the fuel building (outside the containment building). When located outside the containment building, the two areas are connected by a fuel transfer system which carries the fuel through a normally closed opening in the reactor containment. In this case, spent fuel is removed from the reactor vessel by a manipulator crane and placed in the fuel transfer system. In the spent fuel pool, the fuel is removed from the transfer system and placed into storage racks. After a suitable decay period, the fuel can be removed from storage and loaded into a shipping cask for removal from the site. Spent fuel pools are typically 12m or deeper, with the bottom equipped with storage racks designed to hold fuel assemblies removed from the reactor. A reactor’s pool is specially designed for the reactor where the fuel was used and situated at the reactor site.

High-Density Racks

As was written, subcriticality of the spent fuel pool is ensured by:

- the design of the spent fuel pool,

- requirements on boric acid diluted in water,

- limiting of stored fuel (e.g., fuel enrichment, assembly burnup)

Today, spent fuel is stored in so-called high-density racks or the maximum-density rack (MDR). Fuel assemblies can be stored in about one-half the volume required for storage in standard racks using such racks. Higher storage densities have been achieved without the risk of a nuclear chain reaction by adding neutron-absorbing materials (typically boron) to storage racks and baskets and dissolved in the water. These racks incorporate (boron-10) or other neutron-absorbing material to ensure subcriticality. Boron-10 is generally present in the chemical form of boron carbide (B4C) within a metal matrix (e.g., Boral and Metamic (trademark of Metamic, LLC)) or a polymer matrix (e.g., Boraflex (trademark of BISCO), Carborundum, and Tetrabor). However, borated stainless steel incorporates the boron-10 atoms into the alloy composition.

In the high-density rack design, the spent fuel storage pool may be divided into two separate and distinct regions, which are considered separate pools for criticality considerations. In Region 2, maximum reactivity fuel is not allowed to load, while it can be loaded in the racks of Region 1 of the pool.

The most conservative approach requires that the multiplication factor, assuming flooding with pure water and infinite geometry, does not exceed 0.95 with full loading of the maximum anticipated enrichment. To satisfy this design criterion, the assumptions in the criticality evaluation are as below:

- The fuel assemblies have the maximum approved initial enrichment with the highest reactivity in the fuel’s lifetime and without the control rods (burnable poisons may be considered).

- In the flooding condition, all soluble poison is assumed to have been lost. Specify that the limiting keff of 0.95 (5% subcriticality) be evaluated without soluble boron.

- The array of the fuel assemblies can be taken as infinite geometry or with reflective boundary conditions.

- The effect of structural material and the fixed neutron absorber can be considered.

- Unless the double contingency principle is taken, the presence of the boron in moderation should not be considered. This principle shows at least two independent, unlikely and concurrent incidents have to happen to lead to a criticality accident.

Burnup Credit

In criticality licensing of spent fuel pool, taking credit for the decrease in fuel reactivity due to fuel burnup is known as burnup credit. Burnup credit is similar to boron credit. The concept of burnup credit is taking credit for the reduction in reactivity due to irradiation of nuclear fuel when the criticality safety analysis is carried out for the spent fuel. In spent fuel storage, criticality analyses have generally required to assume that fuel is at its peak reactivity, which is generally the fresh fuel. But in the spent fuel pool, most fuel assemblies have higher burnup with lower reactivity.

The reduction of reactivity is a combinative effect of:

- the net reduction of fissile nuclides,

- the production of neutron-absorbing nuclides (non-fissile actinides and fission products)

In the high-density rack design, the spent fuel storage pool may be divided into two separate and distinct regions, which are considered separate pools for criticality considerations. There are two kinds of storage racks:

- The storage racks are applied to the spent fuel assemblies for which the burnup values must equal or exceed the burnup value credited in the criticality safety calculation. (Region 2)

- The storage racks applied to the spent fuel assemblies assumed non-irradiated, with the maximum reactivity (Region 1).

It should be clear that the burnup credit is not an attempt to reduce the safety margins in criticality safety. It is to reduce the analysis conservatism and reduce the uncertainties in safety margins by a more accurate safety analysis. The fresh fuel assumption can be very conservative and significantly reduce the capacity for a storage or cask volume. The issue is complicated by ensuring adequate administrative controls and measurement systems exist to prevent higher reactivity fuel from being placed in storage racks. Regulators also have concerns about verifying the accuracy of being allowed burnup credit.

For example, abnormal conditions should include consideration of fuel assemblies loaded into storage racks not approved for storage (e.g., fuel not meeting minimum burnup requirements stored in burnup credit storage racks).

Special reference: Introduction of Burn-up Credit in Nuclear Criticality Safety Analysis. Guoshun You, Chunming Zhang, Xinyi Pan. Nuclear and Radiation Safety Center of MEP.