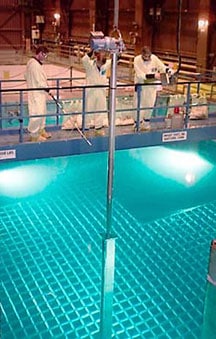

A spent fuel pool (SFP) is a storage pool for spent nuclear fuel from nuclear reactors. A spent fuel pool may be located inside the containment building or the fuel building (outside the containment building). When located outside the containment building, the two areas are connected by a fuel transfer system which carries the fuel through a normally closed opening in the reactor containment. In this case, spent fuel is removed from the reactor vessel by a manipulator crane and placed in the fuel transfer system. In the spent fuel pool, the fuel is removed from the transfer system and placed into storage racks. After a suitable decay period, the fuel can be removed from storage and loaded into a shipping cask for removal from the site. Spent fuel pools are typically 12m or deeper, with the bottom equipped with storage racks designed to hold fuel assemblies removed from the reactor. A reactor’s pool is specially designed for the reactor where the fuel was used and situated at the reactor site.

Spent fuel pools are fitted with stainless steel and aluminum racks that hold the fuel assemblies and are lined with stainless steel to prevent leaking. No drains would allow the water level to drop or the pool to become empty. The plants have a variety of extra water sources and equipment to replenish the water that evaporates over time or in case of a leak. Plant personnel is also trained and prepared to respond to a problem quickly. The water serves two purposes: it cools the fuel and shields workers at the plant from radioactivity. Although water is neither high density nor high Z material, it is commonly used as a gamma shield. Water provides a radiation shielding of fuel assemblies in a spent fuel pool during storage or transport from and into the reactor core. Although water is a low-density and low Z material, it is commonly used in nuclear power plants because these disadvantages can be compensated with increased thickness.

To conserve space, in all plants, open storage racks were replaced with so-called high-density racks that incorporate (boron-10) or other neutron-absorbing material to ensure subcriticality. Fuel assemblies can be stored in about one-half the volume required for storage in standard racks using such racks.

High-Density Rack – Burnup Credit

In criticality licensing of spent fuel pool, taking credit for the decrease in fuel reactivity due to fuel burnup is known as burnup credit. Burnup credit is similar to boron credit. The concept of burnup credit is taking credit for the reduction in reactivity due to irradiation of nuclear fuel when the criticality safety analysis is carried out for the spent fuel. In spent fuel storage, criticality analyses have generally required to assume that fuel is at its peak reactivity, which is generally fresh fuel. But in the spent fuel pool, most fuel assemblies have higher burnup with lower reactivity.

The reduction of reactivity is a combinative effect of:

- the net reduction of fissile nuclides,

- the production of neutron-absorbing nuclides (non-fissile actinides and fission products)

In the high-density rack design, the spent fuel storage pool may be divided into two separate and distinct regions, which are considered separate pools for criticality considerations. There are two kinds of storage racks:

- The storage racks are applied to the spent fuel assemblies for which the burnup values must equal or more than the burnup value credited in the criticality safety calculation. (Region 2)

- The storage racks applied to the spent fuel assemblies assumed non-irradiated, with the maximum reactivity (Region 1).

It should be clear that the burnup credit is not an attempt to reduce the safety margins in criticality safety. It is to reduce the analysis conservatism and reduce the uncertainties in safety margins by a more accurate safety analysis. The fresh fuel assumption can be very conservative and significantly reduce the capacity for a given storage or cask volume. The issue is complicated by ensuring adequate administrative controls and measurement systems exist to prevent higher reactivity fuel from being placed in storage racks. Regulators also have concerns about verifying the accuracy of being allowed burnup credit.

For example, abnormal conditions should include consideration of fuel assemblies loaded into storage racks not approved for storage (e.g., fuel not meeting minimum burnup requirements stored in burnup credit storage racks).

Special reference: Introduction of Burn-up Credit in Nuclear Criticality Safety Analysis. Guoshun You, Chunming Zhang, Xinyi Pan. Nuclear and Radiation Safety Center of MEP.

Interim Storage

Interim storage is a temporary solution that plays a central role in managing the most highly radioactive materials: spent nuclear fuel and vitrified waste resulting from reprocessing such fuel. Since spent nuclear fuel is compact, plant operators can store fuel assemblies for a long time. In nuclear power plants, spent nuclear fuel is stored underwater in the spent fuel pool on the plant, and plant personnel moves the spent fuel underwater from the reactor to the pool. Over time, as the spent fuel is stored in the pool, it becomes cooler as the radioactivity decays away. After several years (> 5 years), decay heat decreases under specified limits so that spent fuel may be reprocessed or interim storage.

Most countries with nuclear programs use some type of interim storage as their back-end strategy. They have explicitly decided to take a “wait and see” approach to spent fuel management, leaving their spent fuel in interim storage, which leaves both the reprocessing and direct disposal options open for the future. As the name implies, the wait-and-see option proposes interim storage until some solution for permanent storage and disposal is developed in the future. For many operators, the spent fuel also represents a strategic material since the spent nuclear fuel still contains about 96% of reusable material. Storing spent fuel and waste for several years allows heat release and radioactivity to subside. Despite the continued debate over the future of the fuel cycle, a quiet consensus has developed that simply storing spent fuel while developing more permanent solutions is an attractive approach for the near term.