Pressure Control

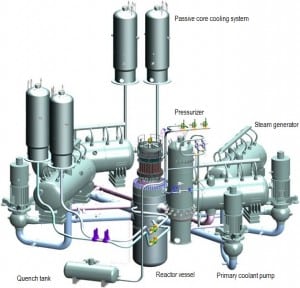

Source: gidropress.podolsk.ru

used with permission of АО ОКБ “ГИДРОПРЕСС”

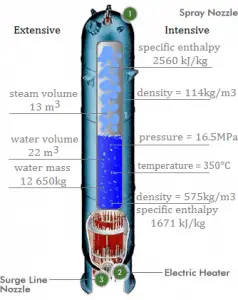

Pressurized water reactors use a reactor pressure vessel (RPV) to contain the nuclear fuel, moderator, control rods, and coolant. They are cooled and moderated by high-pressure liquid water (e.g., 16MPa). At this pressure, water boils at approximately 350°C (662°F). This high pressure is maintained by a pressurizer, a separate vessel connected to the primary circuit (hot leg), and partially filled with water heated to the saturation temperature (boiling point) for the desired pressure by submerged electrical heaters.

On the other hand, there are spray lines to decrease pressure inside the pressurizer, which in turn causes a decrease in pressure in the reactor coolant system. These spray lines spray reactor coolant from the cold leg of a loop into the steam space and condense a portion of the steam. The quenching action reduces pressure and limits the pressure increases.

The temperature in the pressurizer can be maintained at 350 °C (662 °F), which gives a subcooling margin (the difference between the pressurizer temperature and the highest temperature in the reactor core) of 30 °C. Subcooling margin is a very important safety parameter of PWRs since the boiling in the reactor core must be excluded. The basic design of the pressurized water reactor includes such a requirement that the coolant (water) in the reactor coolant system must not boil. To achieve this, the coolant in the reactor coolant system is maintained at a pressure sufficiently high that boiling does not occur at the coolant temperatures experienced while the plant is operating or in an analyzed transient.

The pressure applied to the reactor system can also affect reactor operation by causing changes in reactivity. The reactivity changes result from changes in the density of the moderator in response to the pressure changes. Although water is considered to be incompressible, in reality, it is slightly compressible (especially at 325°C (617°F)). The effect of pressure in the primary circuit has similar consequences as the moderator temperature. Compared with the effects of moderator temperature changes, changes in pressure have a lower-order impact on reactivity. The causes are only in the density of the moderator, not in the change of microscopic cross-sections.

For example, as the system pressure rises, the moderator density increases and results in greater moderation, less neutron leakage, and therefore the insertion of positive reactivity. A reduction in the system pressure results in the addition of negative reactivity. In two-phase systems such as boiling water reactors (BWR), however, the effects of pressure changes are more noticeable because there is a greater change in moderator density for a given change in system pressure.

Over-pressure Relief System

Part of the pressurizer system is an over-pressure relief system. If pressurizer pressure exceeds a certain maximum, there is a relief valve called the pilot-operated relief valve (PORV) on top of the pressurize, which opens to allow steam from the steam bubble to leave the pressurizer to reduce the pressure in the pressurizer, thus leading to reduction of pressure in the whole system. This steam is routed to a large relief tank in the reactor containment building, where it is cooled and condensed back into a liquid and stored for later disposition. There is a finite volume to these tanks. If events deteriorate to the point where the tanks fill up, a secondary pressure relief device on the tank(s), often a ruptured disc, allows the condensed reactor coolant to spill out onto the floor of the reactor containment building, where it pools in sumps for later disposition.

The pressurizer is also equipped with a safety valves system (“safety system”), which is also routed to the relief tank. The safety valves system is used for emergency pressure reduction during emergency conditions.

Typical Pressures in Nuclear Engineering

- Typically most nuclear power plants operate multi-stage condensing steam turbines. These turbines exhaust steam at a pressure well below atmospheric (e.g., at 0.08 bar or 8 kPa or 1.16 psia) and in a partially condensed state. In relative units, it is a negative gauge pressure of about – 0.92 bar, – 92 kPa, or – 13.54 psig.

- A high-pressure stage of condensing steam turbine at nuclear power plant operates at steady state with inlet conditions of 6 MPa (60 bar, or 870 psig), t = 275.6°C, x = 1

- A boiling water reactor is cooled and moderated by water like a PWR, but at a lower pressure (e.g., 7MPa, 70 bar, or 1015 psig), which allows the water to boil inside the pressure vessel producing the steam that runs the turbines.

- Pressurized water reactors are cooled and moderated by high-pressure liquid water (e.g., 16MPa, 160 bar, or 2320 psig). At this pressure, water boils at approximately 350°C (662°F), which provides a subcooling margin of about 25°C.

- The supercritical water reactor (SCWR) is operated at supercritical pressure. The term supercritical in this context refers to the thermodynamic critical point of water (TCR = 374 °C; pCR = 22.1 MPa)