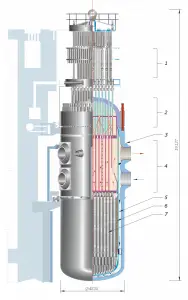

1) Control Element Drive Mechanism

2) Reactor vessel head

3) Reactor pressure vessel

4) Coolant inlet-outlet nozzles

5) Downcomer for coolant

6) Neutron reflector

7) Fuel assemblies

Source: www.wikipedia.org

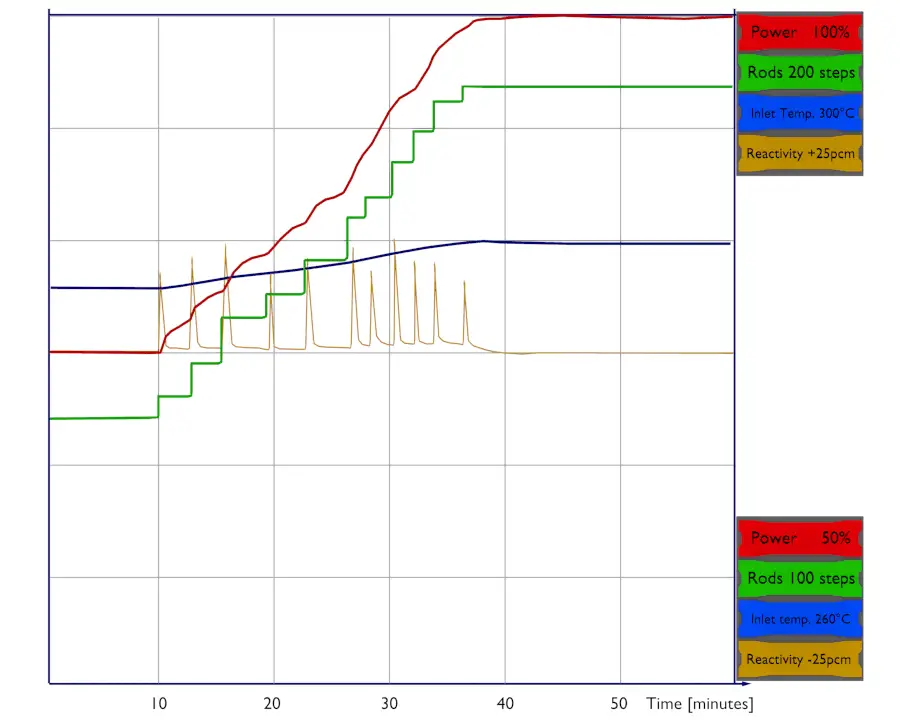

In general, the reactor thermal power and the outlet temperature of the coolant from the reactor core are controlled by manipulating several factors which affect the core’s reactivity. In PWRs, these factors are especially:

- position of control rods,

- the concentration of boric acid in the RCS

- core inlet temperature

Control Rods

Control rods are rods, plates, or tubes containing a neutron absorbing material (material with high absorption cross-section for thermal neutron) such as boron, hafnium, cadmium, etc., used to control the power of a nuclear reactor. Control rods usually constitute cluster control rod assemblies (PWR) inserted into guide thimbles within a nuclear fuel assembly. The absorbing material (e.g., pellets of Boron Carbide) is protected by the cladding, usually made of stainless steel. They are grouped into groups (banks), and the movement usually occurs by the groups (banks). The typical total number of clusters is 70. This number is limited, especially by the number of penetrations of the reactor pressure vessel head.

A control rod is removed from or inserted into the reactor core to increase or decrease the reactivity of the reactor (increase or decrease the neutron flux). Control rods (insertion/withdrawal) influence the thermal utilization factor. For example, control rods insertion causes the addition of new absorbing material into the core, and this causes a decrease in thermal utilization factor.

Compared with the chemical shim, which offset positive reactivity excess in the entire core, with control rods, the unevenness of neutron-flux density in the reactor core may arise because they act locally.

The concentration of Boric Acid

In pressurized water reactors, chemical shim (boric acid) is used to compensate for an excess of reactivity of reactor core along the fuel burnup (long term reactivity control) as well as to compensate for the negative reactivity from the power defect and xenon poisoning during power increase to nominal power.

The concentration of boric acid diluted in the primary coolant influences the thermal utilization factor. For example, an increase in the concentration of boric acid (chemical shim) causes the addition of new absorbing material into the core, and this causes a decrease in the thermal utilization factor.

Compared with burnable absorbers (long-term reactivity control) or with control rods (rapid reactivity control), the boric acid avoids the unevenness of neutron-flux density in the reactor core because it is dissolved homogeneously in the coolant in the entire reactor core. On the other hand, high concentrations of boric acid may lead to a positive moderator temperature coefficient, which is undesirable. In this case, more burnable absorbers must be used.

Moreover, this method is slow in controlling reactivity. Normally, it takes several minutes to change the boric acid concentration (dilute or borate) in the primary loop. For rapid changes of reactivity, control rods must be used.